Everyone loves a good paper shopping bag—until the handle breaks.

A torn handle can ruin a customer’s experience, damage the product inside, and in the worst cases, hurt your brand image. That little strip of paper (or fabric, or rope) might seem small, but it carries the weight of the entire product—literally and figuratively.

Yes, paper bag handle design is the difference between a reliable shopping experience and a disappointing mess. Strength comes from smart structure, quality materials, and real-world testing. It’s not luck—it’s engineering.

Let’s dig into what makes a handle durable, comfortable, and safe, and how we at GreenWing engineer our paper shopping bags to handle pressure—gracefully.

Why Should Handle Design Be Taken Seriously?

A paper bag handle isn’t just decoration. It’s the single point of stress between the bag and the customer’s hand.

If the handle fails, the entire bag is worthless.

If it holds strong—it becomes part of a premium experience.

In today’s packaging world, eco-friendly is non-negotiable.

But performance must come along for the ride.

A sustainable bag that breaks easily defeats its own purpose.

That’s why at GreenWing, we treat handle design as a functional structure, not just an accessory.

What Types of Handles Are Common?

There are many handle options out there, but they’re not created equal.

Here are the most common types:

Twisted Paper Rope Handles

- Eco-friendly, low-cost, and recyclable

- Moderate strength

- Great for retail or takeaway

Flat Paper Handles

- More surface contact, better load distribution

- Slightly higher strength

- Often used in supermarkets or daily use bags

Fabric / Ribbon Handles

- Premium feel

- High comfort and tensile strength

- Often seen in high-end fashion bags

Die-Cut Handles

- No external parts, built into the bag

- Clean look but weaker

- Often reinforced with inner lining

Composite Material Handles

- Combine paper with synthetic threads or fibers

- Balanced performance and aesthetics

How Are Handles Attached to Paper Bags?

Attachment is everything.

You can have the best handle in the world—but if it’s glued wrong, it’s useless.

We typically use four methods:

- Threaded + punched holes: Rope handles go through holes and get knotted or glued

- Adhesive-mounted: Flat or ribbon handles glued directly to the inner walls

- Heat-sealed: Rare for paper but works with coated or laminated surfaces

- Riveted: Often used for fabric or premium bags for mechanical strength

A key detail? The connection structure.

We use reinforcement pads or thickened layers under the contact points.

These spread the force across a wider area and prevent tearing from concentrated pressure.

What Makes a Handle Load-Bearing?

It’s all about physics.

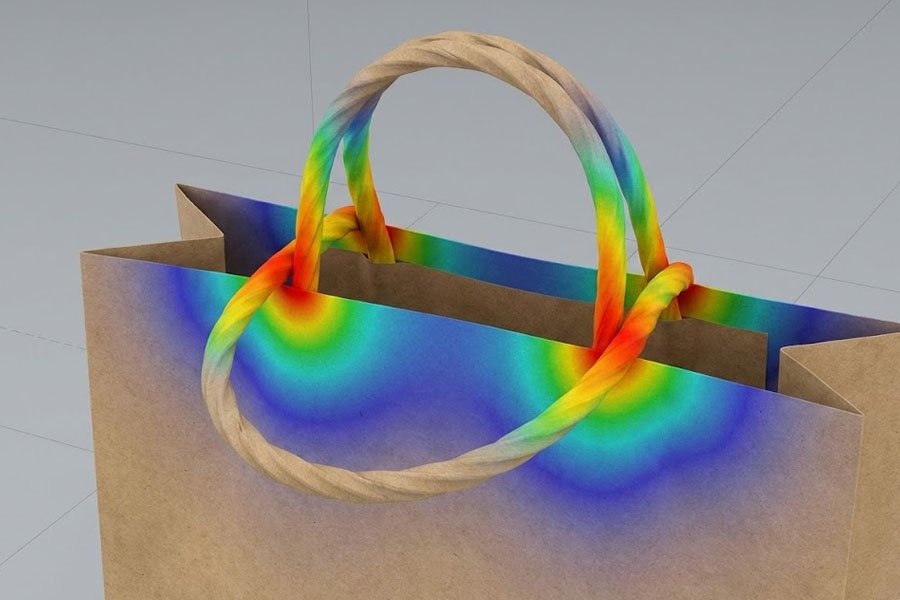

When you lift a bag, the stress travels from the handle into the paper body.

That creates stress concentration points—especially around the connection area.

To avoid breakage, we analyze:

- Handle material tensile strength

- Cross-section shape (flat vs. round)

- Paper weight (e.g., 120g vs. 200g kraft)

- Number and position of attachment points

- Whether the stress is dynamic (swinging while walking) or static (hanging still)

Design by Weight Class

Different bag weights need different structural logic.

- Lightweight (1–3kg): Twisted or flat handles, basic pad reinforcement

- Medium weight (3–8kg): Double-ply paper + thickened adhesive zone

- Heavyweight (8kg+): Reinforced fabric handles, stitched or riveted, extra gusset lining

We don’t guess. We simulate.

We test every new design in both lab and real-world conditions.

What Causes Tear Failure?

Tear resistance isn’t just about the handle. It’s the whole system.

Here are the most common failure modes:

- Handle detachment: Poor adhesive or bad angle

- Connection tearing: No reinforcement patch

- Opening edge tearing: Sharp fold without stress absorption

- Full body tearing: Paper too thin or poorly layered

Tear-Resistant Design Tools

We use a few tricks to make bags tear-resistant:

- Patch reinforcements: Sized based on weight class

- Multi-layer lamination: Especially near the top edges

- Stress relief holes: Reduces tearing at corners or folds

- Edge folding: A single fold can double resistance

- Fiber direction: Aligning fibers to resist pull direction

Our favorite innovation? Honeycomb or cross-fiber lamination.

It boosts tear resistance dramatically without much added weight.

What Materials Actually Perform?

Paper Material

We use kraft paper from 120g to 400g.

Stronger paper = heavier bag capacity.

But weight = cost.

Fiber sources include wood pulp, bamboo, and recycled paper.

We treat paper through coating, calendering, or waterproofing depending on usage.

Handle Material

Let’s talk numbers:

- Twisted paper rope: 7–12 kg breaking point

- Fabric handle: 15–25 kg depending on weave

- Die-cut reinforced: 3–6 kg only

We choose based on use case, not just looks.

Adhesives

We use water-based and hot-melt adhesives.

Water-based is more eco-friendly.

Hot-melt gives stronger initial tack.

Bonding strength must meet minimum 8N/cm² in our quality tests.

How Do We Test Handle and Bag Strength?

This is where it gets technical—and fun.

International Standards

- ISO 12625 (tissue and paper packaging)

- ASTM D4632 (tensile testing of textiles)

- QB/T 1014 (China’s shopping bag standard)

- EU Packaging Directive (for recyclability and strength)

Load Testing

- Static suspension test: Hang 2x intended load for 1 hour

- Dynamic swing test: Simulates walking while carrying

- Drop test: Bag dropped from 1m while filled

- Fatigue test: 5 kg load carried for 100 cycles of up/down motion

We even do tear tests:

- Elmendorf tear test

- Trouser tear method

- Cross-directional tear resistance

What’s Happening in Production?

Modern bag strength starts on the factory floor.

Handle Production

- Twisting machines for rope handles

- Ribbon weaving machines for high-end bags

- Composite forming for special textile-paper handles

Attachment Technology

- Precise punching (±0.5 mm tolerance)

- Temperature-controlled hot melt machines

- Fully automated gluing + pressing systems

Automation

We’ve invested in:

- Automated threading robots

- Vision inspection systems to detect misalignment

- Tension controllers that adjust pressure in real-time

What Can Go Wrong—and How Do We Prevent It?

We’ve seen it all. Here are real failure modes:

- Handle root snapping → glue didn’t cure fully

- Detachment during delivery → wrong adhesive for humid region

- Edge tearing after swinging → no reinforcement pad

We use microscopy and material analysis to diagnose.

Once root cause is found, we fix it—through material, method, or design changes.

No guesswork allowed.

Can Strength Be Sustainable?

Absolutely. In fact, it has to be.

Sustainable Material Use

- Recycled paper wherever possible

- Bamboo pulp for rapidly renewable fibers

- Water-based glue over solvent-based types

Lightweighting

We optimize every structure to use less material, without losing performance.

Sometimes a better fold saves more than a thicker sheet.

Easy Recycling

We push single-material bags—all paper, even the handle.

No plastic linings. No metal eyelets.

No recycling headaches.

What’s Next for Strong Paper Bag Design?

We’re already working on the future.

- Nano-fiber enhanced paper

- Bio-composite handle cores

- Real-time load sensors embedded in bag handles

- Algorithm-optimized folding patterns to maximize strength with minimum mass

- Modular handles for reusability

Strength is getting smarter.

Final Takeaway

A strong, tear-resistant paper bag doesn’t happen by accident.

It’s the result of smart handle design, material engineering, process precision, and real testing.

At GreenWing, we treat every bag as a structure, not a container.

So next time you lift a paper shopping bag, and it just feels right—you’ll know why.