Let me tell you something every serious food brand buyer already knows—but many still underestimate:

Food packaging is regulated.Food-contact paper packaging is highly regulated.And the rules change depending on the map.

Whether you’re exporting croissants to California, tea to Berlin, or snacks to Beijing, the humble paper bag you use must meet strict safety and compliance requirements.

Yes, FDA (US), LFGB (EU/Germany), and GB (China) standards all regulate food-contact paper bags—but each system has its own focus, testing protocols, and substance control logic. For any business working cross-border (like most of our customers), understanding these differences isn’t optional. It’s the key to unlocking safe, smooth, and scalable exports.

So let’s break it down—region by region—and draw the compliance map together.

Why Food-Contact Regulations Matter So Much?

If a paper bag touches bread, coffee beans, or tea leaves—it’s no longer just a bag.

It becomes part of the food contact chain. And that chain is tightly monitored.

Paper bags can carry:

- Residual chemicals from pulp bleaching or coating

- Contaminants from printing inks or adhesives

- Migrating substances from antimicrobial treatments

- Microplastics or metal particles in the worst cases

No regulator wants this.

No buyer can afford it.

No brand survives a recall.

That’s why governments define “food contact material” (FCM) rules—to protect consumer health and enforce safety through compliance.

What Does the FDA Say About Paper Bags in the US?

The United States has one of the most established systems for food packaging safety.

The FDA (Food and Drug Administration) governs it under Title 21 of the Code of Federal Regulations (21 CFR).

Key Frameworks for Paper-Based Packaging:

- 21 CFR Part 176: “Indirect food additives: Paper and paperboard components”

- 21 CFR 178: “Adjuvants, production aids, and sanitizers”

- Threshold of Regulation (TOR) exemptions for substances with very low migration risk

- GRAS status: Generally Recognized As Safe materials

In simple terms:

The paper, coatings, inks, adhesives, and additives used in your paper bag must either be:

✔ Explicitly listed by FDA

✔ Covered by a Food Contact Notification (FCN)

✔ Or be GRAS/low-risk and documented

Especially important for Mike (our ideal buyer):

The supplier must provide a Letter of Guarantee (LOG) affirming compliance with FDA regulations for intended use.

What Does LFGB Mean in Europe (Especially Germany)?

Europe operates under EU Framework Regulation EC No. 1935/2004, which covers all materials that come into contact with food—including paper.

But here’s the twist:

Unlike plastic (which has EU-wide harmonized rules like EC 10/2011), paper and board are not yet fully harmonized across Europe.

Enter LFGB: Germany’s National Regulation

Germany enforces stricter rules under the LFGB (Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch), aka the Food and Commodities Act.

The core idea?

Paper must not:

- Transfer any substance that endangers health

- Alter food composition

- Affect the organoleptic properties (taste, smell, appearance)

Testing Requirements Include:

- Sensory testing (no taste/smell transfer)

- Heavy metals (lead, cadmium, chromium)

- Migrating substances

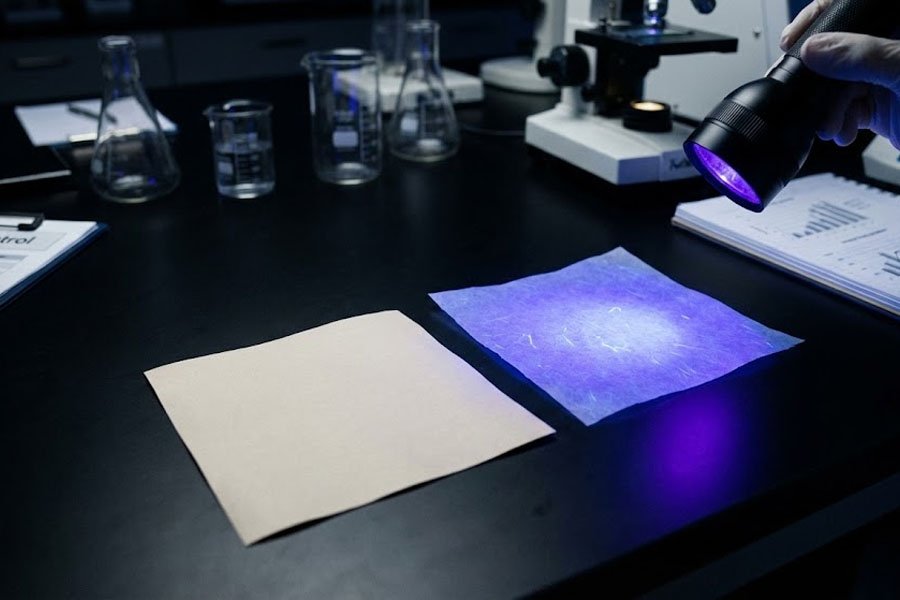

- Optical brighteners

- Fluorescent substances under UV

To pass, suppliers must meet standards from BfR (Federal Institute for Risk Assessment) such as BfR Recommendation XXXVI for paper and board.

At GreenWing, we regularly send paper bags to third-party German labs for LFGB food contact testing—to ensure our clients can legally sell in Germany and EU-wide.

What About China’s GB Standards?

Now we’re back on home turf.

In China, the food packaging safety system is governed by a unified set of GB (Guobiao) National Standards.

It’s precise. It’s evolving fast. And it’s critical for both local and export businesses.

Key Regulations for Food-Contact Paper:

- GB 4806.8-2016: National standard for food contact paper and board

- GB 4806.1-2016: General safety standard for all food contact materials

- GB 9685-2016: Standard for allowable additives in FCM

- GB/T 10004-2008: Performance requirements for paper packaging

Testing scope includes:

- Overall migration limit: ≤10 mg/dm² (aqueous simulant), ≤60 mg/kg (fat simulant)

- Heavy metal content

- Fluorescent whitening agents

- Residual formaldehyde

- pH value

- Decomposable aromatic amines (if printing is involved)

If a bag is printed, coated, or treated for moisture resistance—it needs more layers of compliance.

Here at GreenWing, we maintain full documentation of our raw material sourcing, adhesive specifications, and migration test results to comply with GB regulations.

It’s not optional. It’s our minimum standard.

Comparing FDA, LFGB, and GB: What’s the Difference?

Let me make it simple:

| Aspect | FDA (USA) | LFGB (Germany) | GB (China) |

|---|---|---|---|

| Authority | FDA | BfR + EU Commission | NHC + SAMR |

| Testing Type | Material-based listing | Migration + Sensory + Substance | Migration + Chemistry |

| Additive Controls | FCN / GRAS / TOR | BfR Recommendations | GB 9685 additive list |

| Migration Limits | Defined per material | Strict per simulant | ≤10 mg/dm² / ≤60 mg/kg |

| Certification | LOG / 3rd party test | LFGB Certificate (by lab) | GB Test Report (CNAS lab) |

| Enforcement | FDA recalls + penalties | Strict import checks (esp. DE) | Increasing spot checks |

Each market has unique pain points:

- FDA: Material must be pre-approved

- LFGB: More sensitive to printing chemicals

- GB: Very focused on manufacturing transparency and documentation

So What Should Buyers and Importers Do?

Here’s my advice, based on 15 years in the field:

- Know Your Destination Market One paper bag can’t satisfy every regulation. Define your priority markets and work backward.

- Request Certification from Day One Don’t just ask “is this FDA-approved?” Ask for:

- FDA LOG + test report

- LFGB certificate from SGS/TÜV

- GB 4806 / GB 9685 compliance documentation

- Watch Out for Printed Bags and Additives If your bag is printed or moisture-proofed, it likely involves adhesives, inks, coatings, or even antimicrobial agents. These need extra scrutiny.

- Work With a Factory That Understands Compliance At GreenWing, we have a dedicated compliance team. We know our kraft paper’s source. We test every ink batch. We pass LFGB, FDA, GB on a regular basis. And we can provide the documents before you even ask.

Conclusion

Food-contact paper bag compliance isn’t just legal paperwork—it’s a form of trust.

Whether it’s FDA in the US, LFGB in the EU, or GB in China, each regulation exists to protect people. And as a manufacturer, it’s our job to make compliance invisible but bulletproof.

So next time you’re sourcing paper packaging for your food product, don’t just think about design.

Think about the migration limits, certification paperwork, and whether your supplier truly understands what it takes to ship across borders.

At GreenWing, we do.