You’re sourcing paper bags from China. You want quality and a good price. But somehow, the more you order, the cheaper each bag becomes. Sounds too good to be true?

That’s economies of scale at play. In paper bag production, large-scale orders reduce the average cost per unit because fixed costs—like machine setup, labor, and energy—get spread over more bags. Add bulk material discounts and improved workflow, and voilà: lower prices for you.

So how exactly does that magic happen behind the factory gates? Let me walk you through it.

What Are Economies of Scale in Paper Bag Manufacturing?

Let me break it down simply.

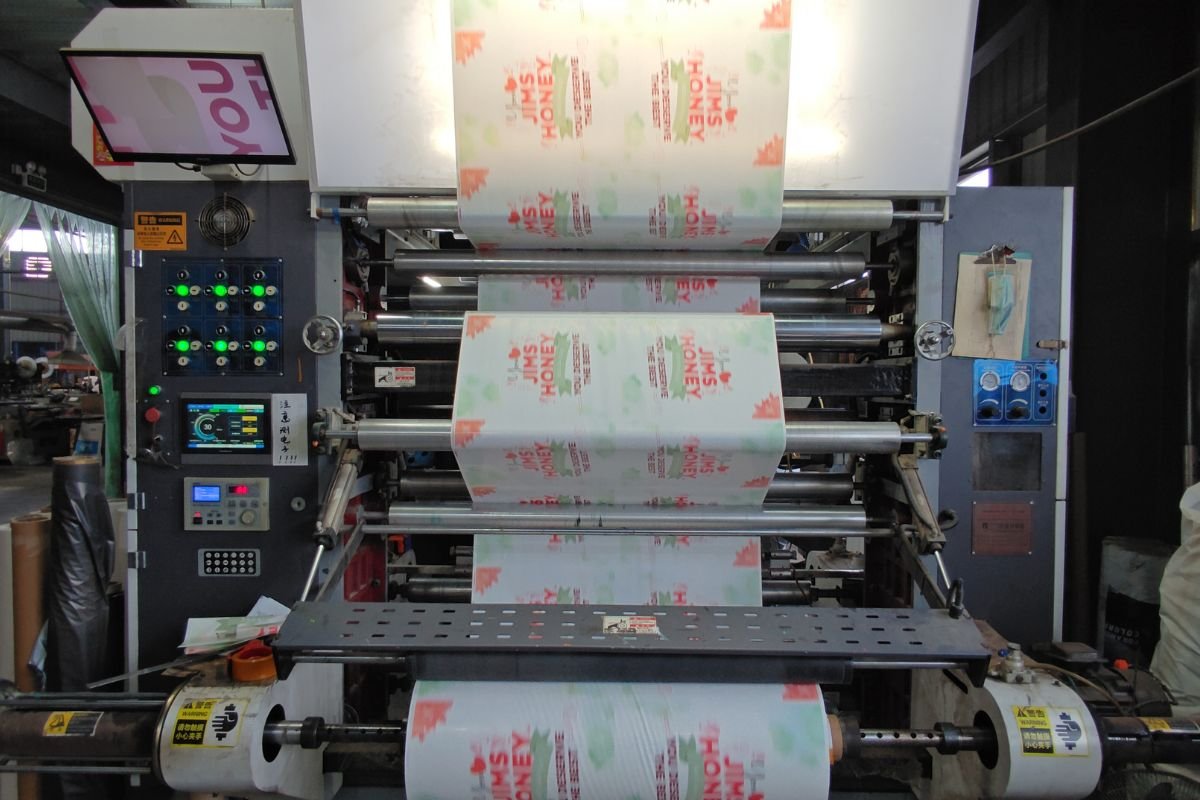

At our 50,000 m² facility in China, we operate over 100 advanced machines. Setting up one of those bad boys to produce your custom kraft takeaway bag takes time and resources. But once we get going? Boom—5 million bags roll out daily.

Now imagine we only run a machine for a tiny 5,000-bag order. The setup cost per bag? High. But if you order 500,000 bags? That same setup cost becomes pocket change per unit.

That’s the magic of economies of scale.

Why Do Larger Orders Cost Less Per Unit?

Here’s the breakdown:

- Fixed Costs Spread Out: Machine setup, labor, electricity—it costs the same whether you order 5,000 or 500,000. The more units we produce, the lower the cost per bag.

- Material Bulk Discounts: We buy raw kraft paper, inks, and glue in massive volumes. Larger orders let us negotiate better material prices—and pass that saving to you.

- Less Waste Per Unit: Every production run has some waste. But when you spread that across a large order, the impact becomes negligible.

- Automation Efficiency: Our automatic bag-making machines are beasts. They love long runs. No need to slow down, reset, or recalibrate. That uninterrupted flow increases productivity.

Does This Affect Quality?

Absolutely—in a good way.

Longer production runs mean more stable machine settings. That means consistent printing, neater folds, and better bag durability. Short runs? They require frequent adjustments, which can sometimes cause slight inconsistencies.

In short: the more you order, the better we can optimize for quality and speed.

What’s the Ideal Order Quantity for Economies of Scale?

There’s no magic number, but here’s a rough guide from our production floor:

- Minimum viable scale: 20,000–30,000 bags. This is when the per-unit price begins to drop significantly.

- Sweet spot: 100,000+ bags. Here, you’re unlocking the full cost efficiency of our factory.

- Max efficiency: 500,000+ bags. At this volume, you’re dancing with our top-tier clients (think Starbucks and JD).

If you’re ordering below 10,000, you’re still welcome here—but you’re paying mostly for setup and logistics. Bulk is where the real savings kick in.

Can Small Brands Still Benefit?

Of course. That’s where group orders, seasonal bundling, or partnering with distributors come in.

Some of our clients in the U.S. food scene band together to place larger orders and share the stock. Others time their orders for Black Friday or Christmas—when they know demand will spike.

Think ahead. Plan smart. We’ll help you combine SKUs or bundle your takeaway and food packaging lines to boost efficiency.

What About Logistics and Storage?

Good question.

Ordering big sounds scary when you think about storage. But we’ve got 20,000 m² of warehouse space. For our VIP clients, we can offer temporary storage and scheduled shipping. That way, you get factory prices—without having to build a new warehouse.

Plus, bulk orders mean fewer shipments. That’s fewer customs headaches, lower freight costs, and less carbon emissions per bag. Everyone wins.

Is This Just About Price?

Not even close.

Bigger orders make us more efficient. That means:

- Faster turnaround

- Less machine downtime

- More consistent product quality

- Better printing alignment

- Happier factory workers (seriously)

And for you? You build stronger partnerships, get priority during peak seasons, and have more room to negotiate custom features—like embossing, foil stamping, or specialty inks.

Why Is This Especially Relevant for U.S. Importers?

Let me speak to my buddy Mike Baker—the 45-year-old purchasing pro running food packaging in the U.S.

Mike, you already know how crucial peak season timing is. Imagine missing your holiday shipment window because your supplier’s tied up with small-batch jobs. Now imagine you placed a big order and got bumped to the front of the line.

That’s not just smart. That’s strategic.

Final Thoughts: Should You Go Big?

If your sales are growing and you’ve got stable SKUs, the answer is yes.

Ordering at scale from a trusted supplier like us doesn’t just reduce cost. It smooths your whole supply chain. And with our one-stop design-to-delivery service? You get flexibility without complexity.

Big orders are smart business. Let’s talk about how we can scale up together.

Related Questions

What’s the difference between fixed and variable costs in bag production?

Fixed costs (like machine setup) don’t change with volume. Variable costs (like paper and glue) do. Scaling up spreads fixed costs thin.

How much can I save by ordering 100,000 instead of 10,000?

Usually 20–40% per bag.

Are there risks in placing large orders?

Only if you work with the wrong supplier. (We’re not that.)

Conclusion

Bigger really is better—when it comes to paper bag production. Let us help you unlock smarter pricing, higher quality, and less stress. Because economies of scale? They’re not just theory. They’re the heart of how we help you win.