When I talk to buyers—especially folks like Mike in the U.S.—I always notice the same struggle. Too many paper bag options, too many specifications, and far too much time wasted comparing materials, weights, and printing techniques. Confusion leads to delays. Delays lead to lost sales seasons. And trust me, nothing keeps procurement awake at night like missing peak season by a week.

That’s exactly why “industry + application” is the smartest way to choose a paper bag. It cuts through the noise. Each industry has its own load requirements, safety standards, and cost expectations. Match the right material to the right use case, and your supply chain becomes faster, cleaner, and far more predictable.

Still with me? Good. Grab your coffee. I’m about to make your next purchasing cycle a whole lot easier.

Why Industry & Application Are the Core of Paper Bag Selection

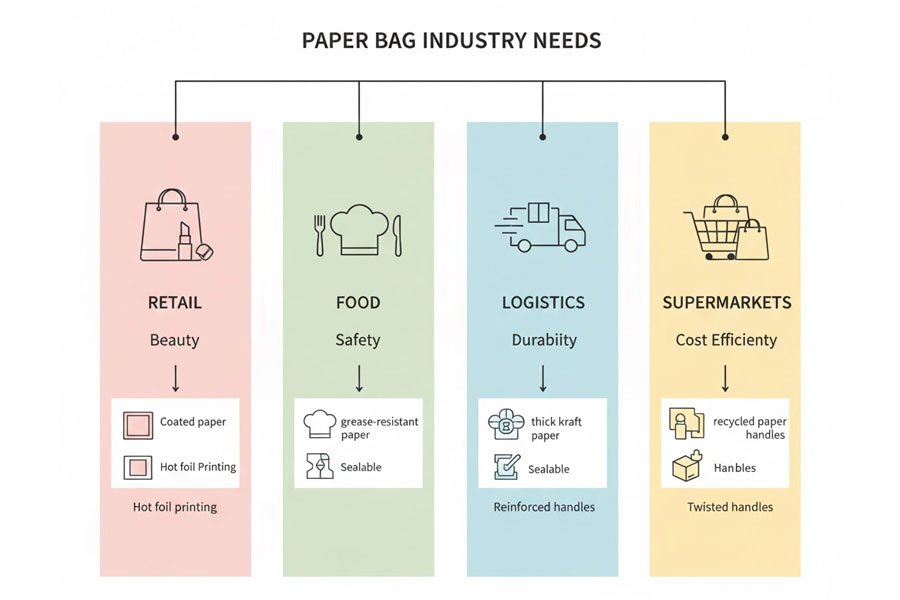

Different industries have drastically different packaging demands.

Retail wants beauty.

Food wants safety.

Logistics wants durability.

Supermarkets want cost efficiency.

And every one of those needs affects:

- Material choice

- Thickness

- Printing method

- Minimum order quantities

- Environmental certifications

- Price per unit

That’s why our team at GreenWing Packaging always asks two questions first:

What industry are you in? And how exactly will the bag be used?

Only then can we recommend something that won’t tear, leak, collapse, or cost you more than it should.

Industry-Based Paper Bag Selection

Below are the six industries where we see the most demand—and exactly what I recommend for each.

1. Retail & Fashion Industry

Typical Needs

- High brand image

- Medium weight capacity (2–5 kg)

- Premium look and feel

- Wide printing flexibility

Retail buyers want bags that look good and last. Whether it’s a boutique handbag store or a cosmetic chain, presentation matters.

Recommended Solutions

1. White Card Paper Bags

Smooth surface. Excellent for high-definition printing.

Perfect for apparel, shoes, beauty products.

2. Coated Art Paper Bags

Supports vibrant printing, foil stamping, embossing.

Ideal for premium brands.

3. Kraft Paper Bags

Eco-friendly and durable.

Great for natural, organic, or sustainability-focused brands.

2. Food & Beverage / Restaurant Industry

Typical Needs

- Food safety compliance

- Grease-resistant and waterproof

- High consumption volume

- Cost control

Food brands cannot afford surprises—especially surprises that smell like oil or leak like soup.

Recommended Solutions

1. Food-Grade White Card Paper Bags

Laminated for grease and water resistance.

Perfect for takeout, bakeries, cafés.

2. Greaseproof Kraft Paper Bags (PE/PLA Coated)

Eco-safe. Cost-effective.

Works well for fast food, pastries, fries, and burgers.

3. Corrugated Paper Bags

Thick, high load capacity.

Great for canned foods or bottled beverages.

3. Supermarkets & Convenience Stores

Typical Needs

- Extremely high daily usage

- Stable supply

- Standardized sizes

- Ultra-low unit price

Supermarkets care about durability and predictability. If a customer’s groceries fall out in the parking lot, guess whose brand gets blamed? Not ours.

Recommended Solutions

1. Standard Kraft Paper Bags

Affordable, strong, customizable.

2. Recycled Paper Bags

Lower cost. Meets eco-regulations.

3. Handle Bags (Twisted or Flat Handles)

Great for household supplies, groceries, packaged goods.

4. E-Commerce & Logistics

Typical Needs

- Anti-compression

- Wear-resistant

- Multi-size compatibility

- Privacy-friendly

- Customer-friendly unboxing experience

E-commerce bags must survive trucks, sorting centers, and customers dropping them twice before opening.

Recommended Solutions

1. Thickened Kraft Paper Bags

3–5 layer composites.

Load range: 5–15 kg.

2. Self-Sealing Paper Mailers

With adhesive strips.

Fast packing for warehouses.

3. Bubble-Lined Kraft Mailers

Shock-absorbing protection for fragile items.

5. Medical & Pharmaceutical Industry

Typical Needs

- Hygiene and safety

- Moisture resistance

- Clear printed labels

- Medication instructions & warnings

Mistakes here are expensive—and dangerous. That’s why medical packaging must meet strict compliance standards.

Recommended Solutions

1. Medical-Grade White Card Bags

Smooth surface for barcodes and labels.

2. Aluminum Foil Laminated Paper Bags

Moisture-proof. Used for premium meds or supplements.

3. Eco Kraft Bags

Used for herbs, traditional medicines, pharmacy pouches.

6. Trade Shows & Gift Industries

Typical Needs

- High aesthetics

- Custom branding

- Medium weight capacity

- Seasonal or event-driven production

Trade show bags often become walking billboards. The better they look, the more people notice.

Recommended Solutions

1. Art Paper Bags

Supports CMYK printing + foil stamping.

2. Specialty Art Paper Bags

Pearlescent textures, embossed finishes.

3. Rope Handle Gift Bags

Comfortable, premium feel.

Application-Based Paper Bag Selection

Now let’s categorize by use case, because two brands in different industries might still need the same functionality.

Daily Shopping Use

- Light items (<2 kg): small white card or kraft bags

- Medium items (2–5 kg): reinforced kraft bag with strong handles

- Heavy items (>5 kg): corrugated paper or multilayer kraft bags

Load-bearing is everything here.

Brand Promotion Use

- Premium brands: art paper + foil stamping + ribbon handles

- Green brands: natural kraft + water-based ink

- Modern brands: white card + trendy illustrations

Your bag becomes your business card.

Food Takeaway Use

- Hot meals: greaseproof kraft with ventilation holes

- Cold drinks: waterproof white card + reinforced base

- Soups/noodles: double-layer laminated kraft + sealed handle

If it leaks, your brand pays.

Gift Packaging Use

- Festive gifts: colorful prints + seasonal themes

- Corporate gifts: logo-printed premium paper + magnetic closure

- Luxury gifting: specialty paper + ribbons + tags

Half the joy of a gift is the packaging.

Logistics Transport Use

- Documents: self-sealing kraft mailers

- Apparel: oversized reinforced bags

- Fragile items: bubble-padded composite paper mailers

Safe delivery = repeat customers.

Selection Decision Table: Quick Matching Tool

| Industry / Use | Material | Load | Price Range | MOQ |

|---|---|---|---|---|

| Retail & Fashion | White card, art paper | 2–5 kg | 0.3–1.5 RMB/pc | 500–1000 |

| Food Industry | Food-grade card, coated kraft | 1–3 kg | 0.2–0.8 RMB/pc | 1000–5000 |

| Supermarket | Kraft, recycled paper | 3–8 kg | 0.15–0.5 RMB/pc | 5000–10,000 |

| E-commerce | Thick kraft, corrugated | 5–15 kg | 0.4–1.2 RMB/pc | 1000–3000 |

| Medical | Medical card, foil laminate | 0.5–2 kg | 0.5–2 RMB/pc | 500–2000 |

| Trade Shows | Art paper, specialty paper | 1–3 kg | 1–3 RMB/pc | 300–1000 |

Common Mistakes & How to Avoid Them

Mistake 1: Only Looking at Price

Cheap bags tear easily, bleed color, or collapse.

They cost more in the long run.

Fix: Always test: handles, thickness, printing clarity.

Mistake 2: Ignoring Environmental Certifications

Regions with strict plastic bans require compliant materials.

Fix: Choose FSC-certified or biodegradable materials.

Mistake 3: Overly Complicated Customization

Too many colors = higher cost + longer production.

Fix: Stick to 1–2 colors + clean branding.

Mistake 4: MOQ Doesn’t Match Real Demand

Overbuying leads to storage problems.

Underbuying drives unit price up.

Fix: Ask for tiered quotes + partial deliveries.

How to Communicate Requirements with Your Supplier

Prepare a Clear Requirement List

- Industry & use case

- Dimensions

- Load requirement

- Printing files

- Budget & MOQ

- Delivery time window

Good communication = fast production.

Ask the Supplier for Technical Information

- Material specs

- Printing limitations

- Lead time

- Quality guarantee

- Sample availability

Sample Testing Checklist

- Load test (walk 50 meters)

- Color accuracy

- Smell & environmental compliance

- Handle comfort

Industry Trends to Watch

1. Sustainable Material Innovation

PLA coatings, straw pulp paper, bamboo fiber—lower carbon footprint.

2. Smart Packaging

NFC tags linking bags to apps or loyalty programs.

3. Modular Customization

Small-batch flexible production (300 pcs MOQ).

4. Circular Economy

Brands offering bag recycling reward programs.

Conclusion

- Define your core needs based on industry and application.

- Compare at least 2–3 suppliers with samples and quotes.

- Start with a small trial order before scaling up.

If you need a recommendation, customization plan, or sample, just send me your specs. As the CEO of GreenWing, I’m here to make your packaging the easiest part of your supply chain—not the scariest.