Quality Management

Excellence in Every Eco-Friendly Packaging Bag

Our Quality Management System (QMS) is designed to ensure that every bag we produce meets rigorous standards of durability, functionality, and sustainability.

Quality Control for Paper Bags

Our quality control (QC) process for paper bags is detailed and tailored to ensure that each bag meets our high standards of quality, durability, and eco-friendliness.

Raw Material Quality Check

We start by inspecting the paper stock and other materials (like inks and adhesives) used for making the bags.

This includes checking for the right weight, thickness, and fiber strength of the paper, as well as ensuring eco-friendly and non-toxic inks and adhesives are used.

Design Accuracy Verification

Before production, the design specifications, including dimensions, graphics, and color matches, are rigorously verified against the client’s requirements.

We use color-matching systems to ensure that the printing on the bags meets the exact color specifications.

Machine Calibration

Our bag-making machines are calibrated for precision cutting, folding, and gluing.

We ensure that the machines are set up to produce bags that are consistent in size, shape, and strength.

In-Line Production Monitoring

During the production process, QC personnel closely monitor the manufacturing steps.

They check for uniformity in the bag’s construction, including the strength of seams and the accuracy of folds and cuts.

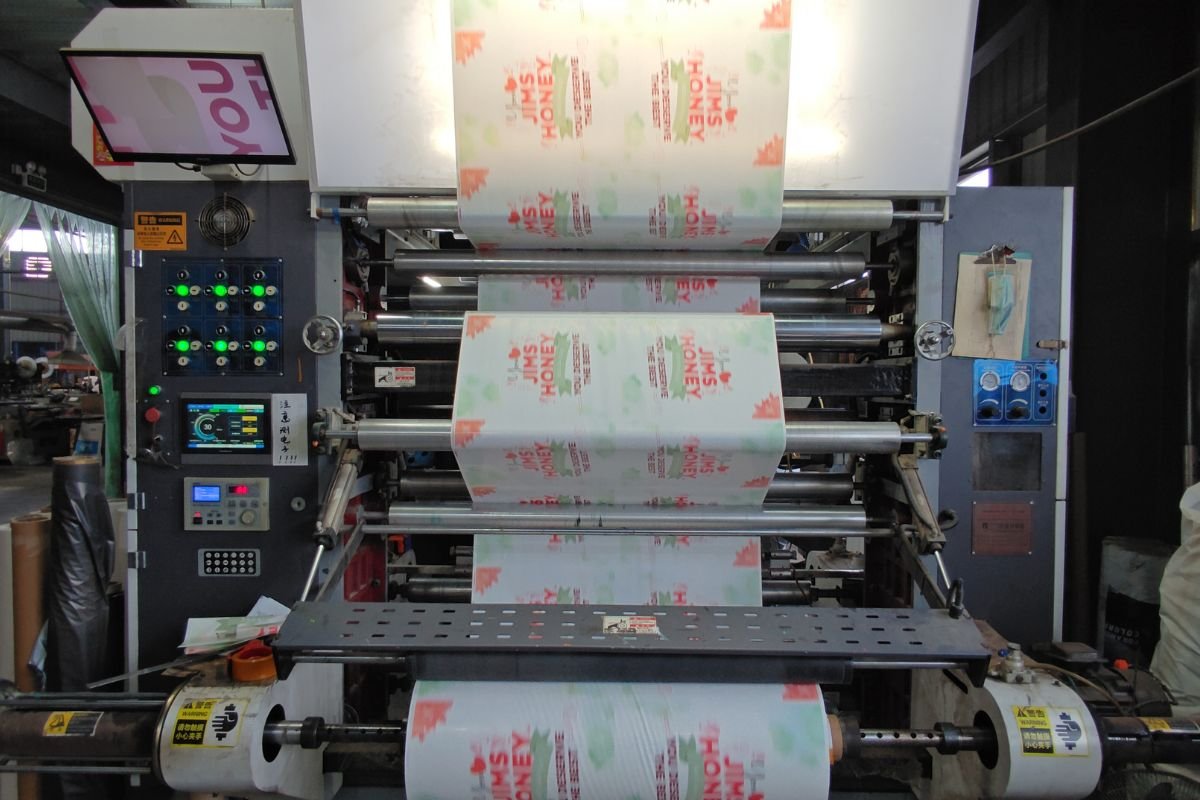

Print and Graphic Quality Inspection

Post-printing, we inspect the bags for any smudging, blurring, or misalignment in the graphics.

The clarity and sharpness of logos and text are scrutinized to ensure high-quality visual presentation.

Strength and Durability Testing

The paper bags undergo tests to assess their load-bearing capacity and durability under various conditions.

This includes testing the handle strength and the bag’s resistance to tearing or deformation.

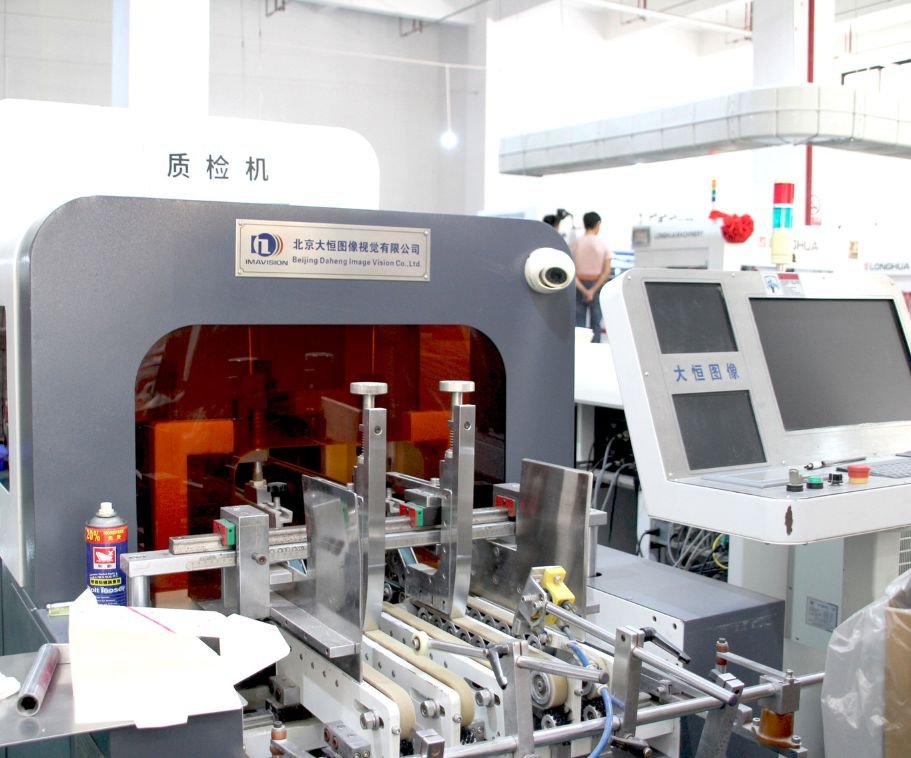

Final Product Inspection

Finished bags are randomly selected for a thorough inspection.

This final check ensures that the bags meet all the set criteria, including aesthetic and functional aspects.

Packaging and Dispatch Check

The way the bags are packed for shipping is crucial to prevent damage.

We ensure that they are adequately protected, especially in corners and edges, to withstand transportation stresses.