Paper Cement Bags Manufacturer

Heavy-Duty Paper Cement Bags

Paper Cement Bags are engineered with multi-layer kraft and optional PE liners, offering maximum strength, moisture resistance, and clean discharge. More sustainable and durable than traditional plastic sacks.

Hot Paper Cement Bags According to Customer Feedback

Paper Cement Bags Types

Paper Cement Bags are designed in various types to meet high-load, moisture-proof, and efficient filling needs in cement and construction industries.

- Valve Paper Cement Bags

- Open Mouth Paper Cement Bags

- Sewn Paper Cement Bags

- Pinch Bottom Paper Cement Bags

- Block Bottom Paper Cement Bags

- Laminated Paper Cement Bags

- PE-Coated Paper Cement Bags

- Moisture-Resistant Paper Cement Bags

- Multi-Wall Kraft Paper Cement Bags

- Custom Printed Paper Cement Bags

Paper Cement Bags Customization

Paper Cement Bags can be fully customized to ensure maximum strength, protection, and branding for various cement products and loading systems.

Customize dimensions and weight capacity from 25kg to 50kg based on your cement needs.

Choose multi-wall kraft, PE coatings, or liners for added durability and moisture control.

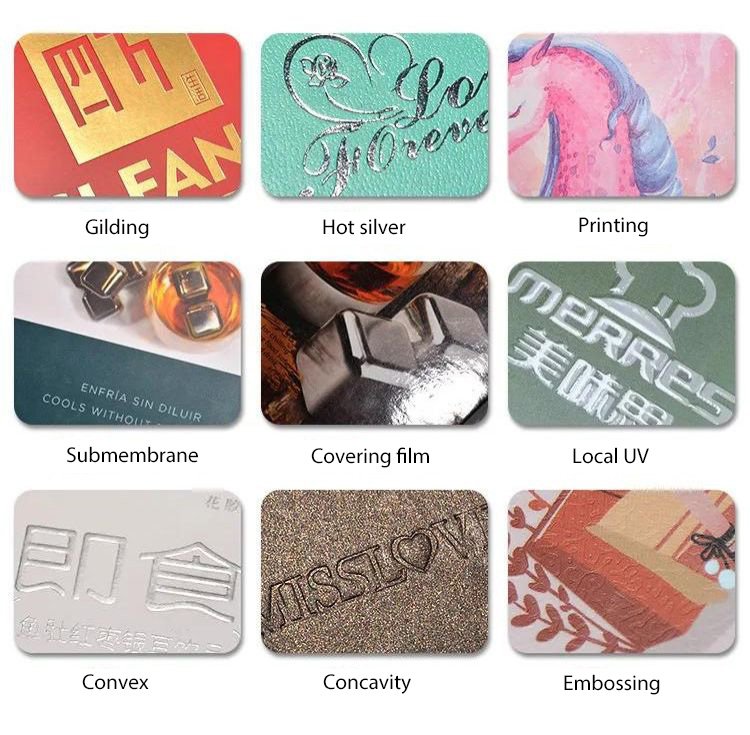

Apply your logo, handling instructions, and safety warnings with high-quality industrial printing.

Select valve, sewn, or pinch closures for efficient filling and secure transport.

Still not find what you're looking for? Contact our consultants for more available products.

How to Customize Paper Cement Bags

Step 1: Consultation

Discuss your Paper Cement Bags requirements, including material strength, size, weight capacity, and custom printing needs.

Step 2: Design

Share your artwork or collaborate with us to create a professional design for your Paper Cement Bags with clear branding and instructions.

Step 3: Manufacturing

Once approved, we produce your Paper Cement Bags using advanced equipment and strict quality checks for heavy-duty performance.

Step 4: Delivery

Finished Paper Cement Bags are securely packed and shipped with reliable logistics to ensure safe, on-time delivery to your facility.

Paper Cement Bags Manufacturing

Paper Cement Bags are manufactured with reinforced materials and precision processes to ensure maximum durability for heavy-duty cement packaging.

Material Preparation – Select premium kraft paper and optional PE liners to achieve the required strength and moisture resistance.

Printing – Apply high-quality logos, product details, and handling instructions using durable industrial inks.

Bag Forming – Assemble multi-layer Paper Cement Bags with advanced machines into valve, open mouth, or pinch bottom styles.

Final Inspection & Packing – Perform strict quality checks, then pack and palletize the Paper Cement Bags for safe transport.

Value-added Services

Value-added services provide extra support to maximize the performance, safety, and efficiency of your Paper Cement Bags supply chain.

Strength Testing

Ensure Paper Cement Bags meet heavy load and drop resistance standards before shipment.

Moisture Control Solutions

Add optional liners and coatings to improve moisture protection in humid conditions.

Custom Palletizing

Arrange pallets for easy unloading and optimized warehouse storage.

Urgent Production Support

Fast-track your Paper Cement Bags orders to meet tight project deadlines.

What our happy customers say

Customer reviews are always the best reflection of our products and services. Take a look at what our customers have said.

“GreenWing’s Paper Cement Bags are tough, reliable, and moisture-resistant. Our bulk orders always arrive on time and ready to use.”

David Wilson

Purchasing Manager

“Excellent printing and top-quality materials. GreenWing helped us customize heavy-duty Paper Cement Bags that perform flawlessly.”

Karen Lopez

Supply Chain Director

“Fast service, durable bags, and great support. GreenWing’s Paper Cement Bags keep our cement secure during transport and storage.”

Mark Johnson

Operations Supervisor

Frequently Asked Questions

Q: What is the typical weight capacity of Paper Cement Bags?

A: Our Paper Cement Bags are designed to handle 25kg, 40kg, and 50kg loads, depending on your requirements.

Q: Can Paper Cement Bags be used in wet or humid environments?

A: Yes, we offer moisture-resistant coatings and PE liners to protect cement in high-humidity conditions.

Q: Do you provide samples before mass production?

A: Yes, free samples of customized Paper Cement Bags are available for testing and approval before production.

Q: Are the bags compatible with automatic filling machines?

A: Yes, our Paper Cement Bags are designed to work efficiently with standard cement filling equipment.

Q: What is the lead time for bulk orders?

A: Standard lead time is 15-25 days after confirming your design and receiving payment.

Q: How are the Paper Cement Bags packaged for shipping?

A: Bags are packed on pallets with waterproof wrapping to protect them during transport and storage.