Packaging Bag Manufacturing Process

A Comprehensive Step-by-Step Guide

We combine advanced technology with environmentally responsible practices to create packaging solutions that stand out in both quality and sustainability.

Material Selection

Our journey begins with the careful selection of materials. We prioritize eco-friendly options like recycled paper and biodegradable elements, ensuring our raw materials align with our environmental ethos and high-quality standards.

Design and Prototyping

Innovation takes shape in our design phase. Here, we turn ideas into tangible prototypes, considering customer feedback and our commitment to eco-friendly design. Our process includes computer-aided design (CAD) modeling and prototyping, ensuring precision and client satisfaction.

Printing and Customization

Utilizing eco-conscious inks and sustainable printing technologies, we bring vibrancy and personalization to our bags. Whether it’s a brand logo or a custom design, our printing process is fine-tuned for excellence and environmental friendliness.

Cutting and Shaping

Precision is key in shaping our packaging bags. Advanced machinery cuts and shapes each bag, optimizing material usage and reducing waste. This stage is where form meets function, guided by our quality-first approach.

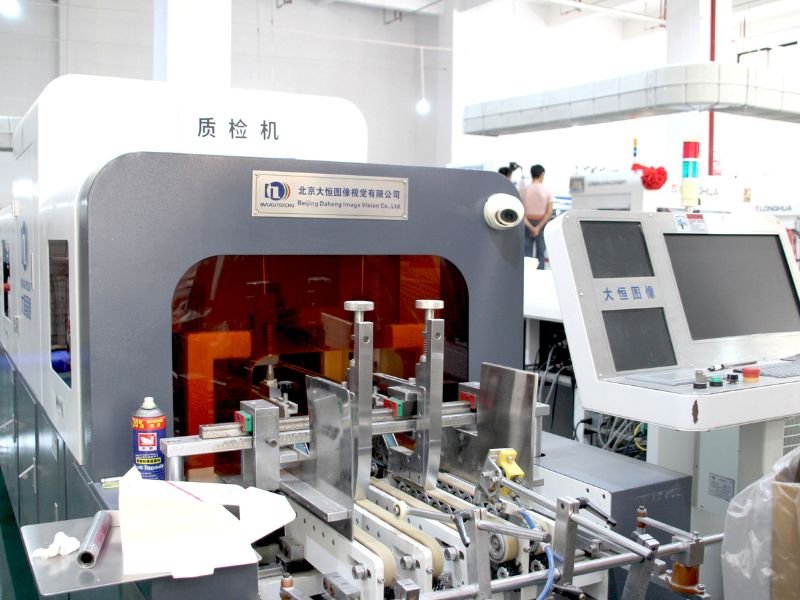

Assembly and Quality Control

Each bag is meticulously assembled, ensuring durability and functionality. Our quality control team rigorously checks every batch, adhering to stringent standards to guarantee only the best products leave our facility.

Packaging and Dispatch

The final step involves eco-friendly packaging of the finished bags, readying them for dispatch. We use sustainable packing materials, reinforcing our commitment to the environment from start to finish.