Open-Top Paper Bags Manufacturer

Customized Open-Top Paper Bags Wholesale

Open-top paper bags offer fast packing, clean presentation, and cost-effective functionality—ideal for food service, retail, and industrial applications.

Hot Open-Top Paper Bags According to Customer Feedback

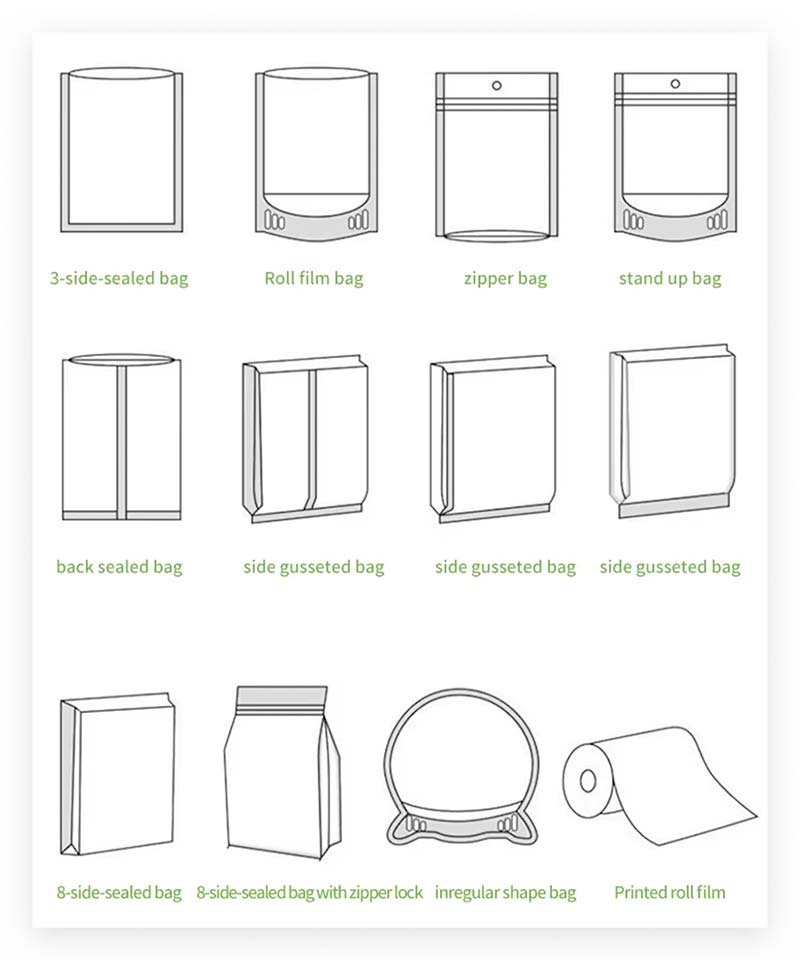

Open-Top Paper Bags Types

Open-top paper bags are preferred for quick packing, visibility, and easy access—especially in high-volume or food-related industries.

- Bakery bread and pastry bags

- Fast food sandwich bags

- Grocery produce bags

- Candy and snack packaging

- Coffee shop takeaway sleeves

- Pharmacy paper bags

- Hardware item packaging

- Food stall or food truck service

- Retail wrapping at point-of-sale

- Bulk spice or tea refills

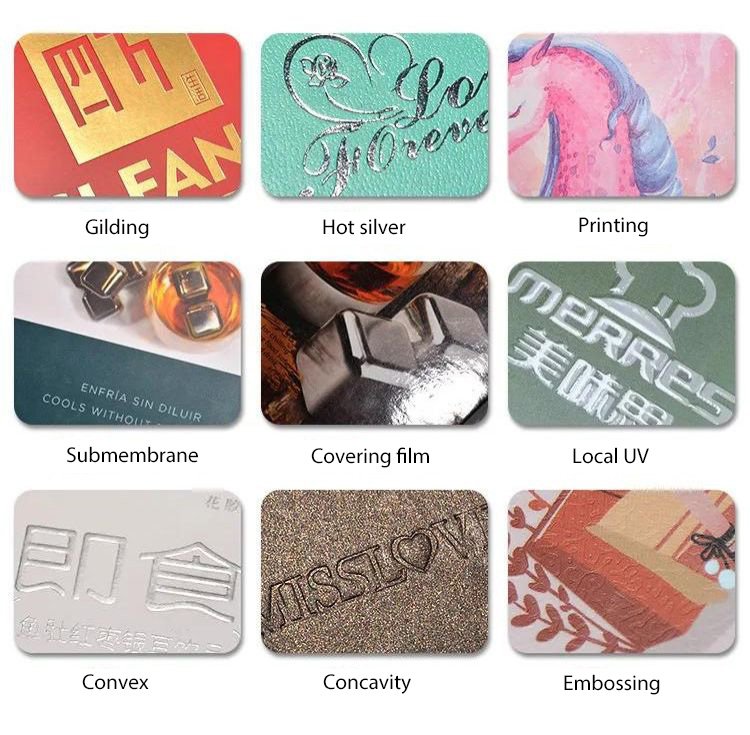

Open-Top Paper Bags Customization

Open-top paper bags can be optimized for speed, branding, and eco-compliance—perfect for daily business operations.

Custom widths, gussets, and heights tailored to your product dimensions.

Choose kraft, white, greaseproof, or recycled paper depending on your industry.

Add branding with 1–8 color printing, inside or outside surfaces.

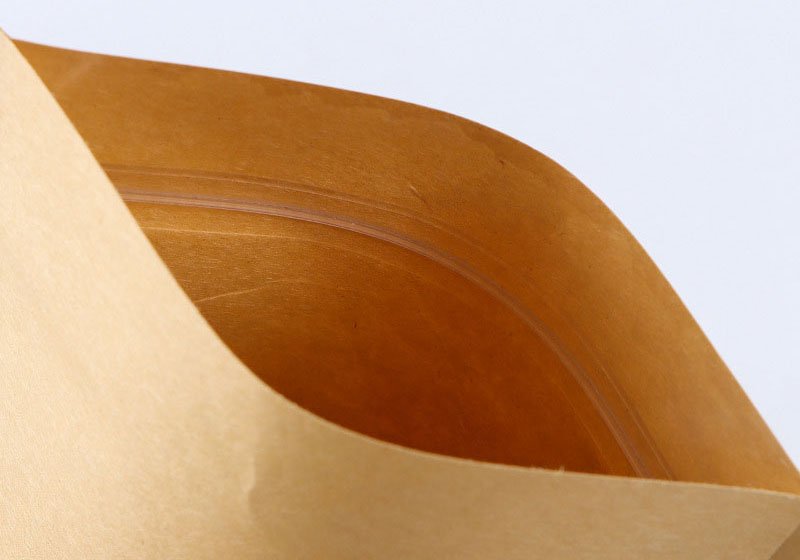

Optional inner coatings for moisture or grease resistance in food packaging.

Still not find what you're looking for? Contact our consultants for more available products.

How to Customize Open-Top Paper Bags

Step 1: Consultation

Define your exact packaging needs for Open-Top Paper Bags—product type, daily usage, material, and artwork.

Step 2: Design

Get bag mockups based on size and graphics. Flexo or offset print plans are prepared for your approval.

Step 3: Manufacturing

Open-Top Paper Bags are produced at high speed with consistent folding, print accuracy, and material strength.

Step 4: Delivery

Bags are packed flat, labeled, and shipped globally with real-time tracking and full export documentation.

Open-Top Paper Bags Manufacturing

Open-Top Paper Bags are manufactured efficiently for high-volume use and consistent structure across every unit.

- Paper Selection – Choose food-grade or standard kraft based on application.

- Printing – Graphics are applied using high-speed flexo or offset printing machines.

- Forming – Paper is cut, folded, and glued into the final open-top shape via automatic machinery.

- Inspection & Packing – Quality checks for size, fold consistency, and print alignment before bulk packing.

Value-added Services

Open-top bags are fast and simple, but value-added services can elevate brand experience and supply chain efficiency.

Pre-Printed Batch Labels

Add expiry dates or product info for retail compliance.

Moisture Barrier Coatings

Protect food or sensitive items with internal linings.

Custom Packaging Sets

Combine bags with matching trays or sleeves for full product kits.

Flexible MOQ Options

Volume flexibility available for seasonal or promotional campaigns.

What our happy customers say

Customer reviews are always the best reflection of our products and services. Take a look at what our customers have said.

“GreenWing’s open-top bags are simple but tough. They keep up with our fast-paced production line without sacrificing quality.”

Jason White

Operations Manager

“These bags are perfect for our bulk herbs and snacks. Clean printing and moisture-resistant options are a big plus.”

Emily Tan

Packaging Buyer

“Fast delivery, solid material, and consistent dimensions. Great partner for our takeaway packaging needs.”

Michael Dunn

Supply Lead

Frequently Asked Questions

Q: Are open-top bags suitable for direct food contact?

A: Yes, we offer food-grade certified paper with optional greaseproof or PE coating.

Q: Can you print both inside and outside the bag?

A: Yes, inside printing is available upon request for added branding or instructions.

Q: What’s the best paper thickness for bakery items?

A: Typically 60–80gsm kraft paper, depending on grease content and product weight.

Q: Are these bags recyclable or compostable?

A: Yes, all kraft and white paper options are recyclable and compostable unless laminated.

Q: Can open-top bags be made with a gusset?

A: Yes, side or bottom gussets can be added for better capacity and structure.

Q: What is your standard lead time?

A: Usually 15–25 days depending on customization and order volume.