Everyone’s saying eco-friendly packaging is the future. But where do you even start a paper bag business? Machines? Suppliers? Customers? Certifications? It’s overwhelming.

I’ve run one of the biggest paper bag factories in China since 2008. Let me give it to you straight.

You start a successful paper bag business by combining market research, strategic product selection, strong supplier partnerships, and lean operations. Focus on a niche, master quality, and scale smart.

Now, let’s dive into the step-by-step blueprint—and avoid the rookie mistakes that cost people thousands.

Is there still a market for paper bags in 2025?

Short answer: yes. Long answer? It’s growing fast.

Global bans on plastic are accelerating. Retail, food, courier, and eCommerce brands are switching to paper. The paper bag market is projected to exceed USD 10 billion in the next few years.

And customers love it. They want “green” and “custom.” If you can deliver both, you’re golden.

Step 1: Decide your niche first

Don’t try to be everything for everyone.

Will you focus on:

- Takeaway bags for restaurants?

- Luxury retail bags for fashion stores?

- Courier bags for eCommerce?

- Eco bags for supermarkets?

Each niche has different size needs, handle styles, printing complexity, and certifications. Pick one and own it.

Want to serve food brands like Mike? Then grease-proof and food-grade certified bags are your battlefield.

Step 2: Create your business plan (don’t skip this)

I know—it sounds boring. But without a plan, you’re winging it.

Include:

- Target market & customer profile

- Pricing strategy

- Production vs. outsourcing

- Marketing & sales channel (Alibaba? Local reps? Trade shows?)

- Start-up budget & expected ROI

Use tools like LivePlan or Canva templates to draft it out.

Keep it lean, but crystal clear.

Step 3: Set up manufacturing (or source from experts like us)

You have two paths:

Option A: Manufacture in-house

- Invest in machines (bag-making, printing, die-cutting, handle attaching)

- Hire trained operators

- Handle raw material sourcing (kraft paper, glue, ink)

- Quality control? All on you.

Option B: Partner with manufacturers like GreenWing

- We customize for you

- You focus on branding and distribution

- Lower upfront risk

Pro tip? Start small by outsourcing. Learn the business. Then scale into your own production when you hit consistent volume.

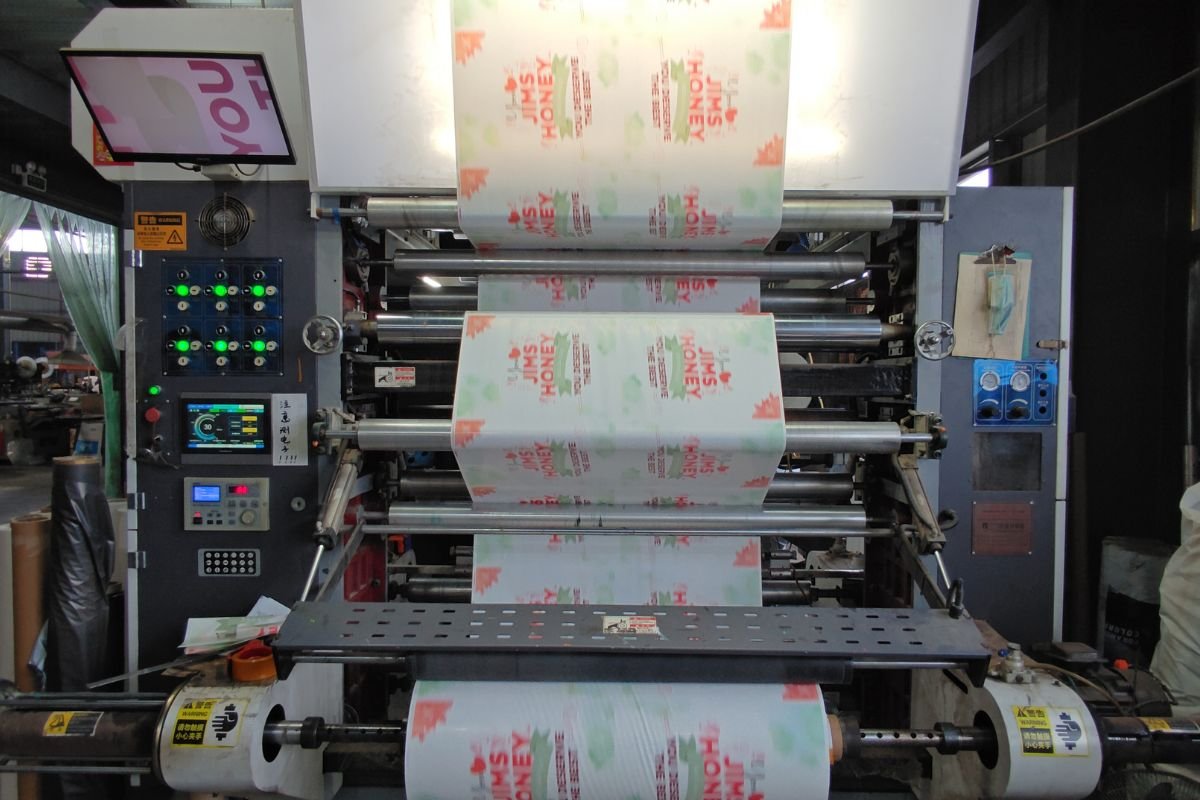

Step 4: Learn about paper types, GSM, and printing

Understanding the materials is non-negotiable.

- Kraft paper: brown or white, recycled or virgin

- GSM: grams per square meter; higher GSM = thicker = stronger

- Printing: flexo, offset, water-based ink, soy ink—each affects cost and eco score

We guide our clients on this every day. If you’re not sure where to start, book a consult.

Knowing your materials = confidence with clients.

Step 5: Certifications, compliance & eco claims

Customers will ask: “Are your bags certified?”

You need to know about:

- FDA food safety compliance (for food-use bags)

- FSC certification (for sustainable sourcing)

- ISO 9001 & 14001 (for quality and environmental management)

- Compostability or recyclability marks

And please—don’t fake it. That’s how suppliers lose long-term business. We’ve rescued clients who got burned that way.

Step 6: Build your brand and go to market

Branding isn’t just a logo.

It’s your product range, your messaging (“eco meets premium”), and your customer service.

Here’s how many successful startups get their first clients:

- Launch a Shopify site + samples

- Cold email niche brands

- Attend trade shows

- List on Alibaba or Faire

- Run a local awareness campaign

Start with value: “We offer low MOQ, certified eco bags, fully custom.” Build from there.

Step 7: Start small, scale smart

Start with one or two SKUs. Maybe one food bag and one takeaway style.

Once sales stabilize, add options:

- Custom printing

- Handle upgrades (ribbon, twisted)

- Specialty finishes (foil stamping, embossing)

Use customer feedback to guide what’s next.

Scaling too fast = inventory headaches. But smart scaling? That’s where real profits happen.

More beginner questions, answered

How much capital do I need?

If outsourcing production: as low as $2,000 for initial stock + marketing.

If manufacturing: $50,000–100,000+ depending on machines.

Is the paper bag business profitable?

Yes. Especially if you carve out a niche, keep quality high, and control costs. Margins can reach 25–40% in the right market.

Can I sell to big clients like Starbucks?

Eventually. But start with local chains, independent restaurants, or boutique retailers.

Big clients = big expectations. Prove yourself first.

Conclusion

Starting a paper bag business isn’t just “trendy”—it’s a real opportunity.

Do your research. Start lean. Focus on quality and relationships.

And when you’re ready for a world-class partner who lives and breathes paper bags… you know where to find me.