You found the perfect design, picked your eco-friendly kraft material, and got all excited about custom printing—only to realize you’ve got no idea how to measure a paper bag properly. Sound familiar?

The short answer?

Measure the paper bag in this exact order: Length (L) × Width (W) × Height (H). Always measure from the inside. Length is the bag’s front width, Width is the side gusset, and Height is the distance from base to top opening.

Stick around—because if you don’t measure your bag the right way, I promise: your product won’t fit, your customer won’t smile, and your money may just fly off with the wind.

Why Does Measuring a Paper Bag Matter So Much?

Let’s be honest. A few millimeters off and suddenly:

- The product doesn’t fit.

- The base caves in.

- Or worse, you can’t even seal the bag.

In the wholesale packaging world, especially for food or retail brands like our client Mike Baker, these aren’t small issues. They’re missed deadlines, wasted inventory, and frustrated retailers.

A well-measured bag saves time, cost, and customer relationships. Period.

The Three Dimensions You Must Know: L × W × H

This is our sacred formula:

L × W × H — Length, Width, Height. Always in that order. Always from the inside.

- Length (L): This is the front-facing side of the bag (the part you’d slap your logo on).

- Width (W): Also called gusset. This is the side fold of the bag.

- Height (H): From the bag’s base to its top, measured straight up.

Say your bag measures 10 × 5 × 15 cm. That’s:

- 10 cm across the front

- 5 cm side gusset

- 15 cm high

And no, rotating the bag doesn’t change the order. Keep it consistent for clear communication with manufacturers like us.

Don’t Forget the Handle Height

If you’re customizing a handheld bag, there’s a fourth unofficial dimension—handle height.

This is measured from the top of the bag to the top of the handle loop. Why does it matter?

Because your customer needs to carry it, not drag it like a sack of potatoes.

For premium brands, we often fine-tune handle height to match ergonomics, aesthetics, and packaging regulations in different countries.

Flat vs. Square Bottom? Know Your Bag Type First

Here’s where most people mess up.

Not all paper bags are created equal. We manufacture:

- Flat paper bags (no gusset or base)

- Square-bottom bags (with a folded-out base)

- Pinch-bottom

- Food-grade with foil lining

Each has different dimensioning needs.

Flat bags? You often just need Length × Height.

Square-bottom? You must include the base width.

If you’re not sure what bag type you’re working with, don’t guess—ask us. Or better yet, send a sample. We reverse-engineer and optimize it for you.

Measuring for Custom Orders? Here’s What We Need

When Mike Baker or someone like him sends us a purchase request, here’s what we expect in terms of specs:

- Inside Dimensions (L × W × H)

- Material Type (e.g., 120gsm white kraft)

- Handle Type & Length (twisted rope, die-cut, etc.)

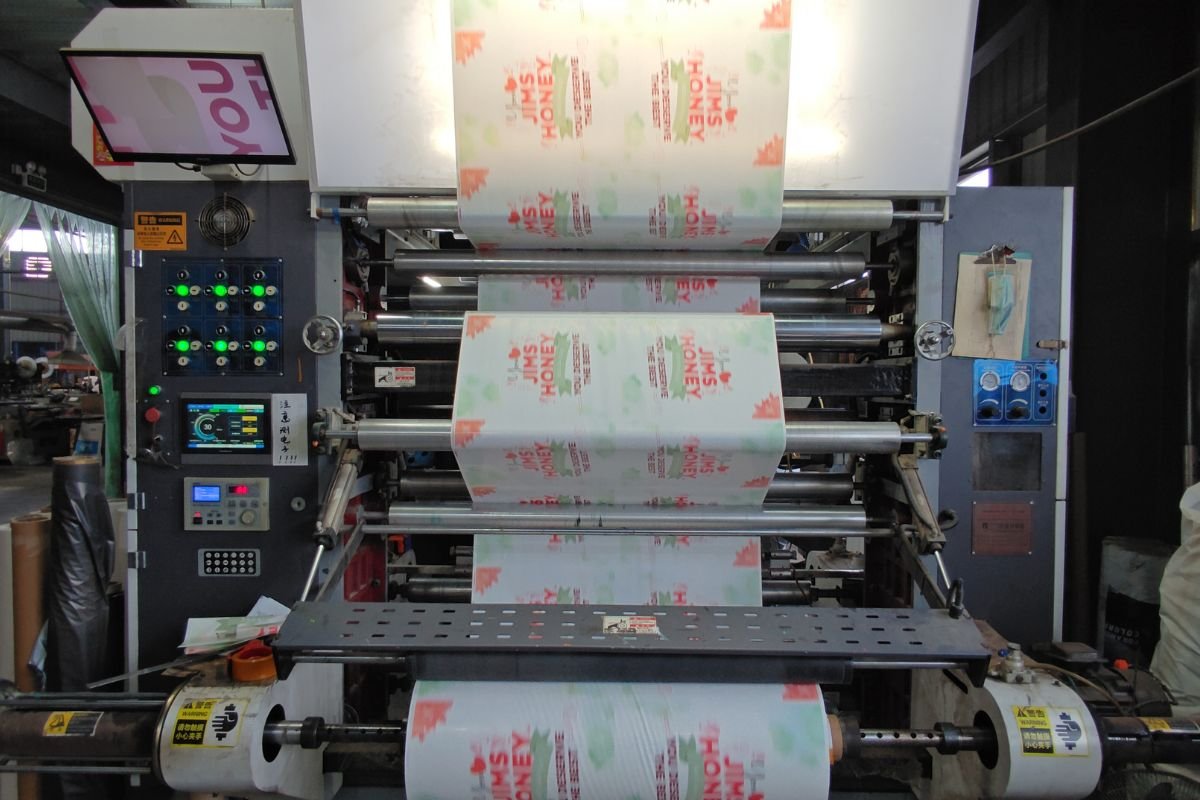

- Printing Requirements (Pantone color? CMYK?)

- Quantity and Delivery Timeline

- Special Certifications Needed (Food grade, FSC, etc.)

Getting measurements wrong can delay sampling, lead to incorrect die-cut molds, and cost serious money in rework.

Our team once got a sample from a client whose listed width was actually their height. We laughed, fixed it, and saved the day—but not everyone gets lucky.

Pro Tip: Always Use an Internal Caliper or Rigid Ruler

No offense to your office tape measure, but it just won’t cut it.

We use rigid rulers and internal calipers to get the job done right. Why?

Because paper bags are flexible. You can pinch, press, or stretch them if you try—but that gives inconsistent results.

And if you’re ordering by the million, every 0.5 mm counts.

Want to Avoid Measuring Mistakes? Ask for a Free Sample Die-Line

If you’re doing custom printing, ask us for a die-line template. It shows where the folds, cuts, and print zones are.

We offer this for free on bulk orders.

We also provide:

- 3D rendering previews

- Test prints

- Pre-shipment inspections

This reduces errors and lets you present visuals to your clients—even before the bags go into production.

More Related Questions

What’s the best size for a takeaway food bag?

Depends on the cuisine. Sushi sets need flat-bottom, burger combos need taller square-bottom bags.

Can I measure an existing plastic bag to match paper?

Yes—but keep in mind that paper isn’t as stretchy. Add 5–10% extra for volume.

What if I need bags for different cup sizes?

We offer tiered customization for cup carriers—from 8oz to 32oz. Send your cup samples, and we’ll create a perfect snug fit.

Conclusion

If you’re serious about quality packaging, learn to measure like a pro. It’s the first step to great design, cost savings, and happy customers. Still unsure? Just ask us—we’re GreenWing. We literally measure success in millimeters.