You’re looking to switch to paper bags — great move. But then comes the big question: “So… how much is this gonna cost me per bag?” And if you’re ordering by the tens of thousands, every penny counts. Miscalculate and boom — margins take a hit.

Paper bag costs typically range from $0.03 to over $1.00 per unit, depending on material, size, printing, handle style, quantity ordered, and customization level. Bulk orders lower the unit price dramatically — especially when working with manufacturers like us in China.

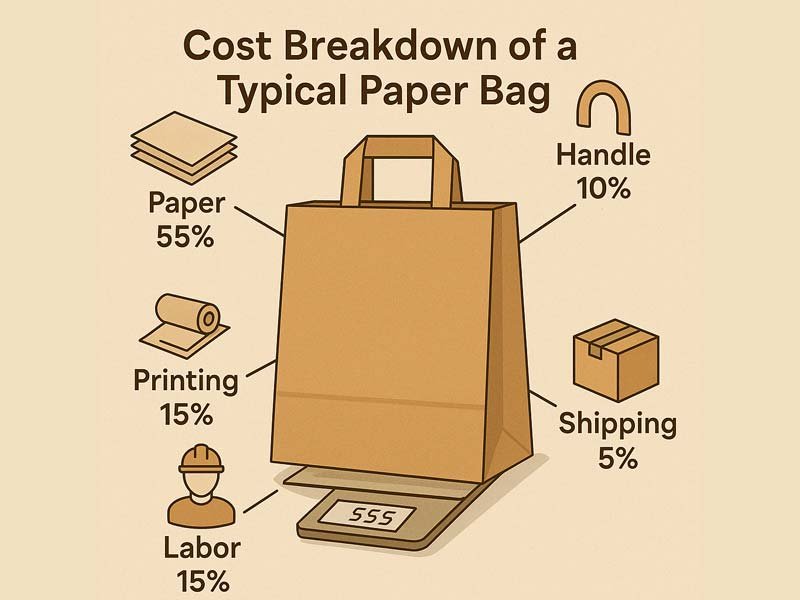

Let’s break down what really goes into that price tag, so you can make smart decisions (and look like a genius at your next sourcing meeting).

What Factors Affect the Price of a Paper Bag?

Let’s get something straight — asking “how much does a paper bag cost?” is like asking “how much does a car cost?”

The answer is: it depends.

Here are the core variables that influence paper bag pricing:

- Size and dimensions

- Paper type and GSM (grammage)

- Printing (none, single-color, full CMYK, Pantone)

- Handle style and materials

- Coating (laminated, PE, UV, etc.)

- Order quantity

- Logistics & shipping method

Even switching from twisted handles to flat ones could shave off 2–3 cents per bag at scale.

Price Ranges by Bag Type (From Our Production Line)

Let me give you some real-world pricing based on what we manufacture daily at GreenWing:

| Bag Type | Typical Cost (USD) | MOQ Notes |

|---|---|---|

| Flat food bag (no handle) | $0.03–$0.07 | Min 50,000 units |

| Kraft takeaway bag (flat handle) | $0.05–$0.12 | MOQ 10,000 units |

| Twisted-handle shopping bag | $0.10–$0.30 | MOQ 10,000–30,000 |

| PE-coated food bag | $0.08–$0.20 | Greaseproof upgrade |

| Laminated luxury retail bag | $0.50–$1.20 | Premium markets only |

You’d be surprised how quickly customizations add up — but also how economies of scale kick in hard after 50k units.

How Does Printing Affect the Cost?

Ah, printing — the beauty and the beast of paper bags.

Here’s how your logo can either save money or blow your packaging budget:

- No printing: cheapest, obviously.

- 1-color flexo: adds $0.01–$0.03 per unit.

- 2–3 color flexo: adds $0.02–$0.06.

- Full CMYK offset or digital: +$0.05–$0.15 per unit.

- Pantone match / metallics: even more.

The key is to balance visual appeal with budget. For food packaging, simple prints often work great. For retail? Splash some color.

Want the visual impact of 4-color without the price tag? We’ll help you cheat a little with clever 2-color designs.

How Order Quantity Impacts Cost

This one’s huge.

Unit price drops dramatically with higher quantity — and I mean dramatically.

Let’s say you want 20x25x10 cm kraft bags with twisted handles:

- 5,000 pcs: $0.28 each

- 10,000 pcs: $0.20 each

- 50,000 pcs: $0.12 each

- 100,000+ pcs: $0.08–$0.10

That’s why we always recommend ordering larger volumes, even if your storage team starts to panic.

With our warehouse capacity (20,000 m²), we can help you stock and ship in waves if needed.

Should I Source Domestically or From China?

Now we’re getting into global sourcing strategy. I like it.

Let’s compare rough averages:

| Supplier Location | Average Cost/Bag | Lead Time | Customization |

|---|---|---|---|

| USA/Canada | $0.25–$1.50 | 2–4 weeks | Limited |

| Europe (esp. Germany) | $0.35–$2.00 | 3–5 weeks | High-quality |

| China (hi 👋) | $0.03–$0.60 | 2–6 weeks (sea) | Very flexible |

We win on price and customization.

Yes, shipping takes longer — but for large B2B wholesale projects, the math almost always favors China.

That’s where GreenWing comes in: we offer reliable production, certification, and competitive pricing — with the factory muscle to back it up.

Are Eco-Friendly or Recycled Bags More Expensive?

Short answer: yes… but not by much.

Here’s what adds cost to eco bags:

- FSC-certified paper: +$0.01–$0.03

- Recycled paper blends: +$0.01–$0.04

- Water-based ink: +$0.005–$0.01

- Compostable glue or coatings: slight bump

We work with many brands trying to hit sustainability goals without breaking budgets. And trust me, eco doesn’t have to mean expensive if you optimize smart.

Plus, some retailers actually prefer the matte, rustic look of unbleached recycled kraft. Bonus: it’s cheaper than coated gloss bags.

Can I Reduce Costs Without Compromising Quality?

Yes. And this is where we shine as your packaging partner.

We help clients cut costs by:

- Reducing GSM while preserving strength

- Optimizing size to reduce waste

- Switching from twisted to flat handles

- Using digital print for small batches

- Consolidating shipping (we even handle freight if you want)

Want a lower-cost version of your current bag? Show us. We’ll reverse engineer it, improve it, and still save you 10–20%.

Sometimes you just need a bag that looks expensive — without actually being expensive. We got you.

Are There Hidden Costs I Should Know About?

Unfortunately… yes. But not with us.

Here are a few hidden costs to watch for:

- Plate charges for flexo printing ($100–$300 per color)

- Mold fees for custom die-cut windows or shapes

- Shipping surcharges during peak season

- Customs duties and VAT in some regions

- Currency fluctuations (USD vs. RMB)

We’re transparent from day one. You’ll get a full quote including bag cost, printing, freight, and even import estimates if needed.

What’s the Most Expensive Paper Bag We’ve Ever Made?

Ooooh, story time.

We once produced luxury paper bags for a French champagne brand — full CMYK, gold foil logo, embossed texture, satin ribbon handles, matte lamination.

Guess the price? $1.75 per bag.

Worth it? Absolutely. That bag probably sold more champagne than the marketing team did.

So yes — sky’s the limit. But most brands don’t need all the bells and whistles. A strong kraft bag with bold print? Timeless.

Conclusion

Paper bag pricing can swing from $0.03 to over $1.00 depending on the specs. But if you understand the factors — size, material, print, and quantity — you can hit the perfect sweet spot between cost, quality, and branding.

Want a fast, accurate quote? Send us your specs — we’ll do the math, cut the fluff, and give you a bag (and price) that works.