Humidity is a sneaky enemy. You can’t see it, smell it, or stop it—but your packaging feels it. From soggy bottoms to wrinkled prints, moisture can destroy a good paper bag before it even hits the shelf.

Humidity affects paper bags by weakening fiber strength, causing warping, softening glue, and damaging printed finishes. Without the right materials, design, and storage, paper bags can lose durability fast in high-moisture environments.

Trust me—I’ve battled humidity for over 15 years in the packaging game. Here’s what I’ve learned and how we’re helping clients beat the heat (and damp).

Why Paper Bags Are Sensitive to Humidity

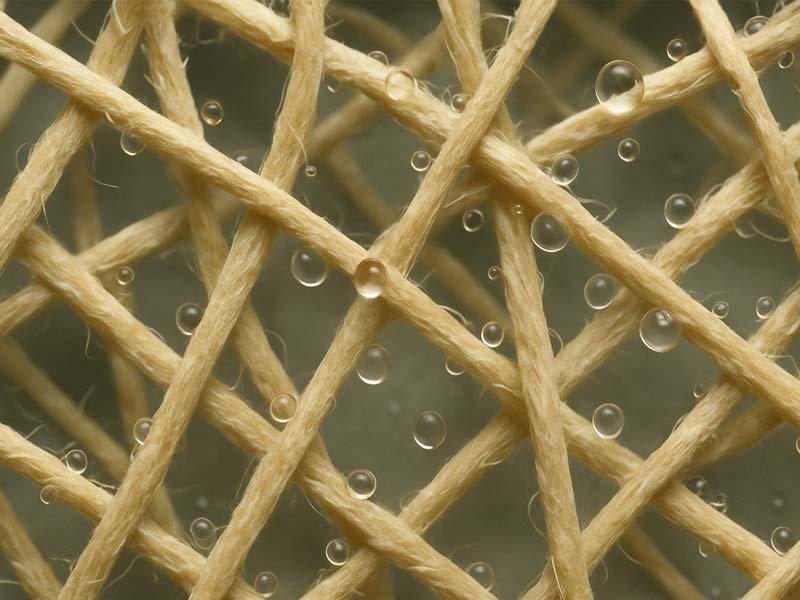

Paper is made from wood pulp—organic, fibrous, and absorbent. It’s basically a sponge in disguise.

When the relative humidity (RH) climbs above 60%, paper starts absorbing moisture from the air. This affects:

- Strength – wet fibers lose tension

- Shape – paper curls or sags

- Weight – added moisture increases shipping cost

- Ink and lamination – may smudge, peel, or bubble

That’s why, especially for clients in tropical or coastal regions, we always assess local climate before recommending paper types.

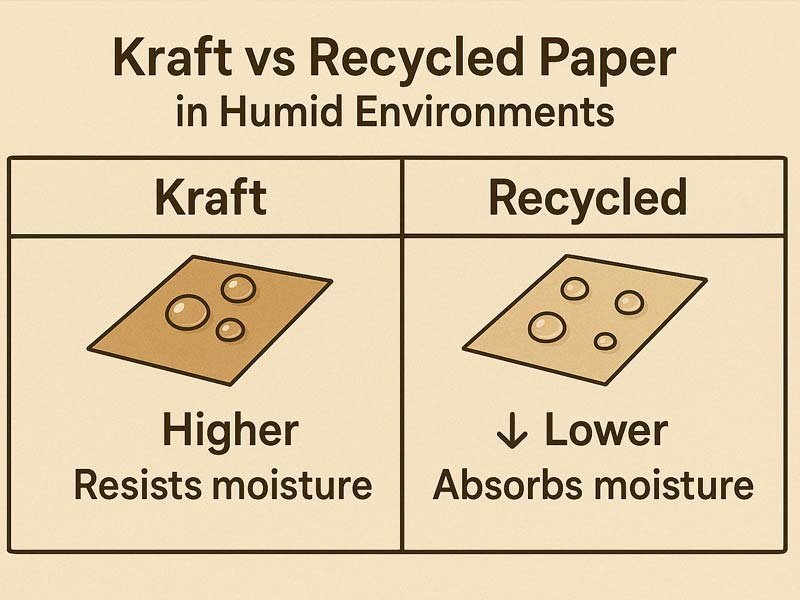

How Different Paper Types React to Moisture

Not all paper is created equal. Some papers handle humidity like a pro. Others? Not so much.

Here’s how common paper types stack up:

- Kraft Paper: High-density, strong fibers, better resistance

- Recycled Paper: Softer fibers, more porous, absorbs moisture easily

- Coated Paper: Can resist water, but coating may bubble or crack in humidity

- Laminated Paper: Resists moisture better, but may delaminate if poorly glued

At GreenWing, we usually recommend virgin kraft paper for clients needing strength and humidity resistance. For food packaging, we can add a moisture-resistant barrier layer—but never at the cost of compostability.

The Glue Factor: Holding It All Together (or Not)

Most buyers don’t think about glue. But when it comes to humidity? Glue is the silent hero—or the first point of failure.

High humidity can:

- Soften glue over time

- Break the seal on handles or side gussets

- Leave bags unusable during shipping or storage

That’s why we’ve developed our own glue formulas, tested at up to 90% humidity. For our clients shipping to Southeast Asia or Florida? This is non-negotiable.

We also perform accelerated aging tests to simulate weeks of warehouse life in just a few days. So you know exactly how the bag performs.

Storage & Shipping Tips to Avoid Humidity Damage

Humidity isn’t just a manufacturing problem—it’s a supply chain problem. Even the best bag can go limp if stored wrong.

Here’s what I always tell our partners:

- Keep bags sealed in original packaging until use

- Avoid direct floor contact—always palletize

- Use desiccants in shipping containers during monsoon seasons

- Choose warehouses with RH control (especially below 60%)

- Rotate stock quickly to avoid long exposure

Our warehouse in China is RH-controlled and our export packaging uses moisture-barrier film liners. If you’re buying from GreenWing, you’re getting dry bags. Period.

How GreenWing Designs Humidity-Resistant Paper Bags

We’ve been obsessed with durability since Day 1. Our approach to beating humidity includes:

- Material Selection: High-strength virgin paper, low porosity

- Glue Tech: Patented waterproof adhesive options

- Lamination Choices: Optional food-safe barrier film

- Design Engineering: Extra folds, double-layer handles, reinforced bases

- Printing Techniques: Water-resistant soy inks and heat-sealed finishes

That’s why our clients—especially in the food and beverage space—trust us to handle packaging for cold, moist, or frozen items.

Mike, our food-brand customer in the U.S., switched to our humidity-proof takeaway bags last year. His complaint before? Bags collapsing before they even reached the customer. That’s gone now.

What You Should Ask Your Paper Bag Supplier

Before placing your next order, ask your supplier these six questions:

- What kind of glue do you use?

- Have your bags been tested in humid conditions?

- Can I see a moisture-resistance certificate or report?

- How do you package bags for export?

- Can you add protective layers without harming recyclability?

- What’s your policy if bags arrive damaged due to humidity?

And if you don’t like the answers? Well, you know who to call.

Conclusion

Humidity is silent—but it can ruin paper packaging if you’re not prepared. From weakened structure to unglued handles, it’s a serious threat to durability. That’s why at GreenWing, we don’t just sell paper bags—we engineer them to survive the real world.

Let’s keep your bags dry and your customers happy.