You’ve invested in a paper bag order. But what shows up? Smudged prints, weak handles, uneven folds. Not only does it hurt your product—your brand suffers too.

At GreenWing, quality control isn’t a final inspection—it’s baked into every step of production. From raw material checks to precision machine calibration and post-production testing, our process ensures consistency, durability, and design accuracy every time.

If you’re trusting us with your packaging, here’s how we protect your trust.

Why Quality Control Is Non-Negotiable in Paper Bag Production

When you’re supplying to big brands or managing your own—whether food takeaway, fashion, or ecommerce—you can’t afford packaging fails.

A ripped bag? A smudged logo? That’s not just a refund. That’s brand damage.

We’ve worked with clients like Starbucks, JD, and Amazon. Their bar is high. So ours had to be higher.

Step 1: Raw Material Inspection

Before anything gets made, we check every batch of incoming materials:

- Kraft paper: Must meet GSM, color consistency, tensile strength

- Inks and adhesives: Non-toxic, food-grade, eco-certified

- Handles and strings: Uniform length, secure bond, load capacity compliant

Every delivery comes with certification and is spot-checked before entering the production floor.

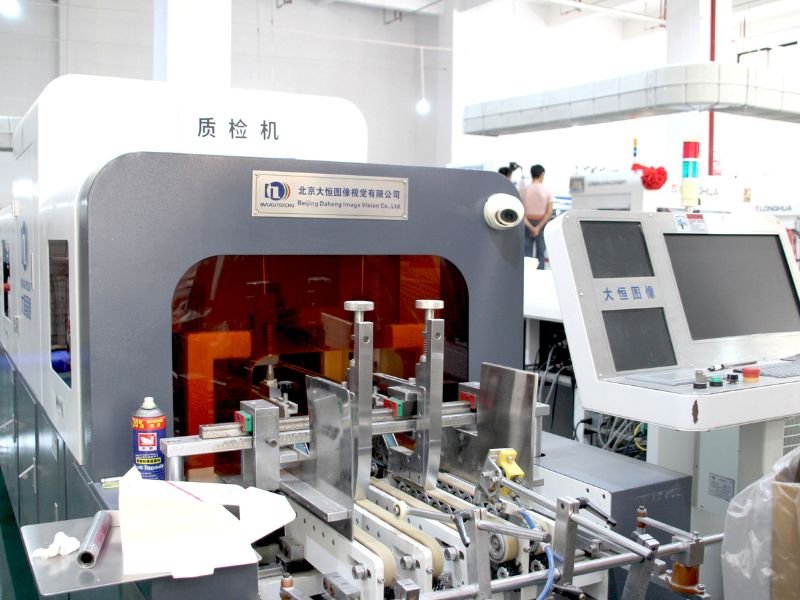

Step 2: Pre-Production Calibration

Our machines may be advanced (over 100+ at our 50,000 m² facility), but they’re only as good as how they’re calibrated.

Before every new run, our technicians:

- Run test bags to validate alignment, die-cut accuracy, and print clarity

- Calibrate cutting blades, glue dispensers, and print heads

- Validate that the bag dimensions match your spec sheet—down to the millimeter

This saves us time. Saves you surprises.

Step 3: In-Line Quality Monitoring

Here’s where we stand apart from the pack.

We don’t wait until the end to check quality. Our machines have real-time sensors and on-the-line inspectors watching for:

- Misprints

- Misalignment

- Defective handles

- Glue failure

- Poor folds or wrinkles

If something’s off, we halt immediately. Recalibrate. Resume.

We call it “running with eyes open.”

Step 4: Post-Production Sampling and Testing

Once production wraps, we take batch samples and run tests:

- Weight testing: Can it handle 2kg? 5kg? We simulate real-life loads.

- Drop testing: Will it survive a fall from a counter? We test that.

- Moisture testing: Especially for food packaging—bags must resist grease, vapor, and condensation.

- Printing durability: Scratch-resistance, rubbing tests, sunlight exposure

Each test follows international standards or your country-specific import guidelines.

Step 5: Certification & Documentation

Quality isn’t just physical—it’s paperwork too.

We provide:

- ISO 9001, FSC, BRC, SGS certificates

- Detailed QC reports

- Photographic documentation for every custom batch

- Optional third-party inspection arrangements (we even help coordinate)

So when customs knock—or your clients ask—you’re covered.

Step 6: Packing and Final Inspection

We’re still not done.

Bags are counted manually, packed in pre-weighed bundles, and labeled for traceability.

Our packers check for:

- Consistent counts

- Clean, damage-free bags

- Correct barcode or label if requested

We add silica gel or protective sheets if your region demands moisture control.

What Are the Most Common Quality Issues We Eliminate?

We’ve seen it all. Here’s what doesn’t happen when you work with us:

- Handle pops off – we use high-tack adhesive and test for tensile strength.

- Ink bleeds – thanks to advanced flexo and offset printing plus curing controls.

- Bag tears – we match material strength to the product’s weight class.

- Printing misalignment – because we pre-print on roll stock before converting.

Your brand image should look as clean as your product. No excuses.

How Do We Handle Quality Complaints?

We rarely get them—but when we do, we act fast.

- We review batch records, including machine logs and inspector notes

- We request photos or videos of the issue

- We reproduce the defect internally to identify the root cause

- Then we offer replacement, refund, or credit—depending on the situation

Our reputation is built on ownership and service. You can trust that we won’t disappear when there’s a bump.

Tips for Buyers: How Can You Verify Our Quality?

Here’s how to keep your peace of mind:

- Request production videos – We’ll show you your job in action.

- Ask for pre-shipment samples – Shipped via DHL, FedEx, or your preferred method.

- Use your own QC agency – We work with most third-party inspectors.

- Get a full QC report – We’ll include batch data and testing outcomes.

You’re not just buying bags. You’re buying predictability. We get that.

What Makes GreenWing’s QC Process Different?

Here’s what sets us apart:

- Dedicated QC team – 18 full-time quality pros

- Digital traceability system – Every bag batch is logged and trackable

- ISO 9001 certified process – We don’t “wing it”—we systematize it

- Zero defect goal – Sounds ambitious? We think so too. But we aim for it anyway.

And maybe most importantly—we care.

Our business only works if you reorder. And you’ll only reorder if the bags work.

Conclusion

At GreenWing, we believe quality isn’t just about avoiding defects—it’s about delivering confidence. That’s why we inspect, test, document, and take ownership at every step. When you partner with us, you’re not just buying bags. You’re buying peace of mind.