Let me guess: You’re sourcing paper bags and someone proudly tells you, “Don’t worry, we use eco-friendly inks and adhesives!” Great. But when you ask, “Which kind? Any certification?” — suddenly, the room gets real quiet.

Eco-friendly inks and water-based adhesives are crucial in sustainable packaging. But using them properly—and certifying them—isn’t just about slapping on a green label. It takes process, testing, and global standards.

If you’re serious about sustainable sourcing, here’s everything you should know—without the fluff.

Why Are Inks and Adhesives So Important in Paper Bag Sustainability?

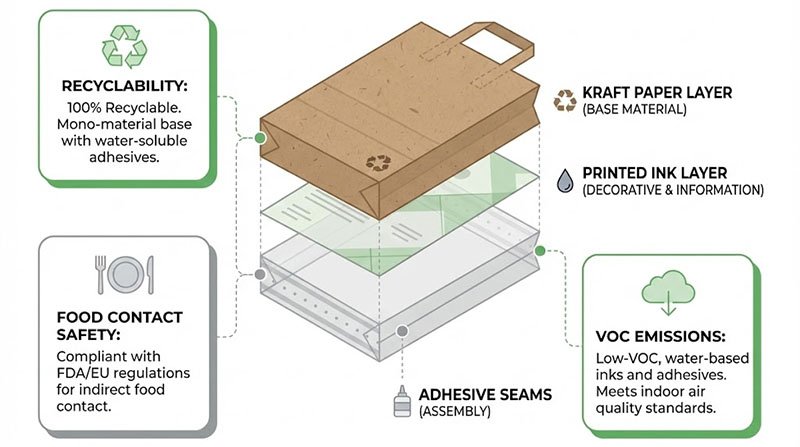

Let’s not sugarcoat it—your paper bag can be 100% recycled fiber, but if it’s glued with solvent-based adhesives and printed with heavy metal inks, it’s not recyclable or compostable.

That’s where eco-inks and water-based adhesives come in. These two components determine:

- Whether the bag can be safely recycled

- If it meets food-contact safety

- How cleanly it prints and seals

- How it performs in hot/cold/greasy conditions

We often say: The materials you don’t see are just as important as the ones you do.

What Are Eco-Friendly Inks?

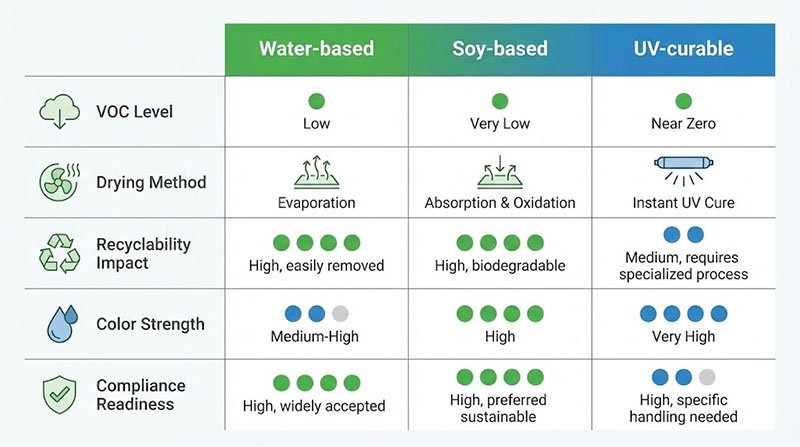

Eco-friendly inks are formulated without harmful solvents, heavy metals, or VOCs (volatile organic compounds). The most common types in paper bag printing are:

- Water-Based Inks – Ideal for kraft bags and food packaging

- Soy-Based Inks – Renewable, low VOC, and great color retention

- UV-Curable Inks – Energy-efficient curing, but limited recyclability

Water-based inks are our go-to. They’re easy to clean, non-toxic, and provide high-quality prints even at high speeds.

Certification to Look For:

- REACH Compliance (EU)

- RoHS Directive

- EN 71-3: Toy Safety Ink Standard

- ASTM D6866 (Bio-based content)

And yes, we provide full test reports and declarations for these.

How Are These Inks Applied on Paper Bags?

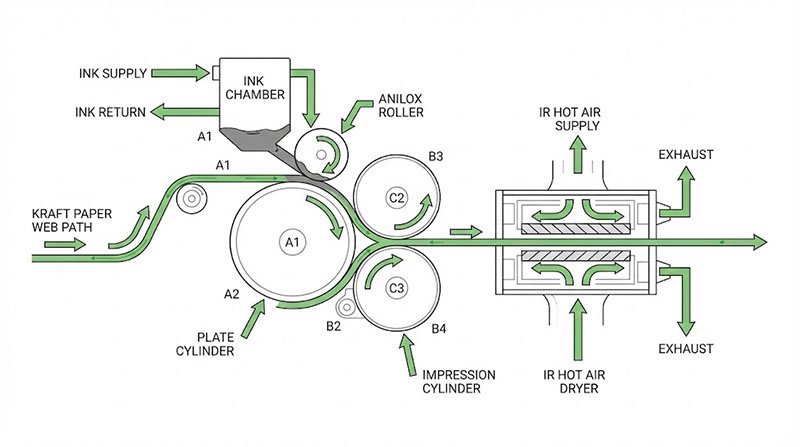

It’s all about the printing method. At GreenWing, we mainly use:

- Flexographic Printing: Best for high-speed, high-volume jobs. Perfect for kraft bags.

- Gravure Printing: Higher precision for glossy or coated paper bags.

Water-based inks are a match made in heaven for flexo. We use anilox rollers that apply consistent, thin layers. This reduces waste and ensures bright, clear graphics—without over-inking.

Also, because water-based inks dry fast (especially with IR dryers), they support efficient production cycles.

What Are Water-Based Adhesives?

Let’s move on to the glue that holds it all together.

Water-based adhesives are made with natural or synthetic polymers dispersed in water. Unlike solvent-based glues, they don’t emit strong odors or toxic VOCs.

Popular types include:

- PVAc (Polyvinyl Acetate): Common for paper-to-paper bonding

- Dextrin-Based Adhesives: Made from starch, excellent for food-safe packaging

- Acrylic Dispersions: Stronger bond, suitable for heavier bags

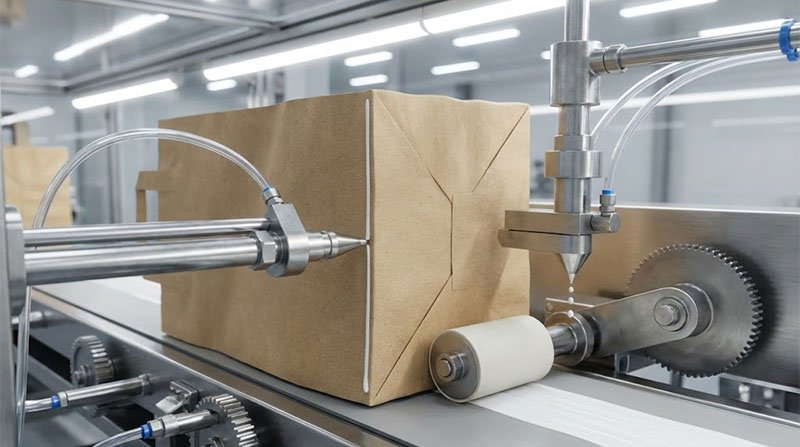

How Are Adhesives Applied in Production?

We use precision nozzles and roller systems to apply adhesives during bag formation. Placement matters—a lot.

- Bottom pasting

- Side seam sealing

- Handle attachment

Each part of the bag may require a different adhesive formula based on weight, use-case, and required shelf life.

We fine-tune our glue application for every client’s bag spec. Whether it’s takeaway food or heavy retail loads, we test adhesion strength and durability every batch.

Certifications & Standards for Inks and Adhesives

Now the meaty stuff—how do you prove your materials are compliant?

For Inks:

- RoHS & REACH: Ensures inks are free from restricted chemicals

- EN71-3: Guarantees safety for inks on packaging potentially used around children

- ISO 2846 & 12647: Print color consistency standards

- FDA/EC Food Contact Compliance: Especially important for food-grade bags

For Adhesives:

- FDA CFR 21.175.105 (USA): For adhesives used in food packaging

- EU 1935/2004 & 10/2011 (Europe): Covers food contact safety

- ASTM D6866: Confirms bio-based content

- Recyclability Tests: Passes repulpability requirements

If a supplier can’t show you these certs or test results—run.

Common Questions from Buyers

Can water-based inks match solvent inks in color and clarity?

Yes, and sometimes better. Modern water-based formulations deliver excellent pigment strength. In flexo printing, we match Pantone colors easily.

Do adhesives weaken under heat or cold?

Only if you’re using the wrong kind. For frozen food or hot-fill items, we use temperature-resistant formulas tested under simulated conditions.

Are these inks and adhesives more expensive?

Not necessarily. While the upfront cost may be slightly higher than traditional materials, the long-term value—regulatory compliance, brand trust, sustainability—pays off.

Can you print heavy coverage designs with eco inks?

Absolutely. Our anilox rollers and plate technology make it possible to run large-coverage prints with minimal bleed or ghosting.

Conclusion

Eco-friendly inks and adhesives aren’t optional anymore—they’re expected. But doing it right means more than slapping on a green icon.

We’ve spent over a decade refining how we print and bond paper bags that are not just sustainable—but also certified, tested, and beautiful.

Need certified materials for your next packaging project? Let’s make it happen.