The world is drowning in plastic waste, and businesses are under pressure to switch to eco-friendly alternatives. But here’s the catch—paper bags often fail the test of strength and durability. Solution? Enter material science. At GreenWing, we’re pushing the limits of what paper can do. Result? Stronger, greener, and smarter packaging.

High-strength paper bags today are not just about holding weight. They are the result of advances in fiber engineering, coatings, lamination, and sustainable material innovation. By combining cutting-edge science with large-scale production, we are making paper bags that rival plastics in strength, while still being fully recyclable and eco-friendly.

If you’re curious about how we get from tree fibers to something strong enough to carry your weekend grocery haul without a tear—keep reading. I’ll break it down in plain language, and yes, a few nerdy details too.

Why Do We Need High-Strength Paper Bags?

Think about it. You buy a hot takeaway meal, the sauce leaks, the bag tears, and you end up wearing your lunch. Or worse—you run a retail chain, and your branded bags collapse in the hands of customers. Not a good look.

The demand for high-strength paper bags isn’t only about convenience. It’s also about global plastic reduction mandates and the shift toward circular economy models. Brands need packaging that can carry weight, withstand moisture, and still decompose responsibly.

And let’s face it—no one wants to pay for a shipment of paper bags that arrive weak and unusable. Strength equals trust.

The Science Behind Stronger Fibers

Here’s the secret. Paper strength starts at the fiber level. Traditional kraft paper is already known for toughness, but now material scientists are mixing in longer virgin fibers with optimized blends of recycled pulp to create a denser, tear-resistant structure.

Some labs are even experimenting with nanocellulose reinforcement. Imagine tiny plant-based crystals that increase tensile strength without adding weight. Think of it as giving paper “muscles.”

At GreenWing, we leverage multi-layer fiber engineering. Outer layers focus on surface smoothness (great for printing), while inner layers maximize tensile load-bearing capacity. It’s like making a sandwich: soft on the outside, strong at the core.

Moisture, Grease, and Heat Resistance—The Game Changers

Let’s be honest. A paper bag is only as good as its performance under stress. Rain, condensation, or oily food can ruin an otherwise solid design. That’s where coatings come in.

Modern solutions include water-based barrier coatings, biodegradable lamination, and even PLA (polylactic acid) films derived from cornstarch. These keep moisture out without compromising recyclability.

We also use heat-sealed edges instead of glue in certain bags. This improves durability and prevents leakage. Customers like Starbucks or McDonald’s want a bag that doesn’t just hold fries—it holds their reputation too.

Printing Meets Strength: More Than Just Looks

You’d be surprised—printing can affect strength. High-quality inks and advanced flexographic printing techniques reduce the risk of weakening bag surfaces. Low-grade inks, on the other hand, can cause cracks or seepage into fibers.

At GreenWing, we use water-based inks that are not only eco-friendly but also designed for surface bonding without damaging fibers. The result? Vivid colors, strong bag walls, and no compromise in load-bearing ability.

And let’s not forget branding. A high-strength bag doubles as a walking advertisement. If it tears in the customer’s hand, your marketing backfires. Strong print + strong material = a win-win.

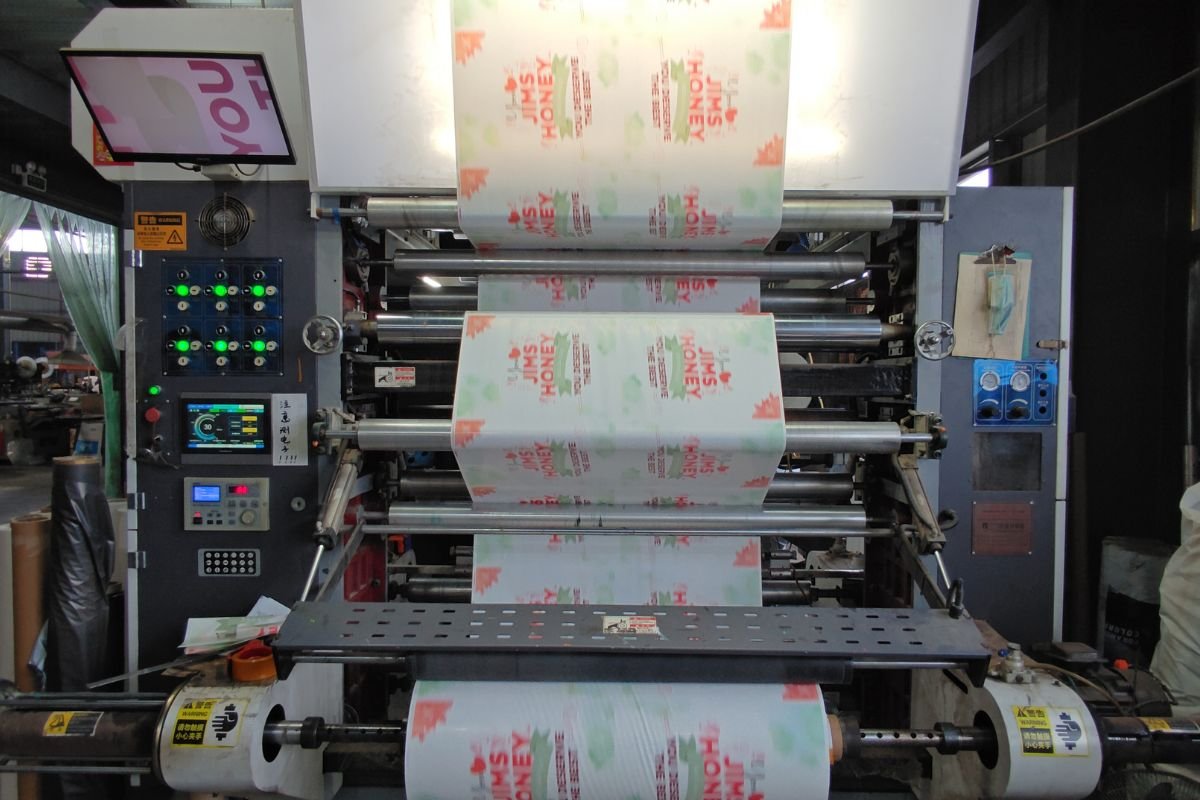

Advanced Machinery: Where Science Meets Production

I love talking about machines. Our factory isn’t just a warehouse—it’s a lab on steroids. With over 100 automatic bag-making machines, we can achieve precision folds, uniform pressure bonding, and consistent strength across millions of bags per day.

Machines like inline strength testers allow us to measure tensile strength, tear resistance, and load capacity in real time. No guesswork—only data.

This is how we scale material science from lab experiments to commercial-level reliability. A bag that performs the same, whether it’s the first in the batch or the five-millionth.

Sustainability Without Sacrificing Strength

Here’s the irony. Some think “eco-friendly” means “flimsy.” Not anymore. With today’s material advances, we can make 100% recyclable bags that handle up to 15 kilograms of weight.

We’ve even tested compostable coatings that biodegrade faster than traditional films but still protect against grease and moisture. That means your bag can carry fried chicken today and feed the soil tomorrow.

And let me add—customers are watching certifications closely. We ensure compliance with FSC certification, FDA food safety standards, and EU packaging directives. Because strength is useless if your bag doesn’t pass regulation.

Case Study: From Fragile to Reliable

A major European retail chain once came to us frustrated. Their existing supplier’s paper bags tore under heavy groceries, costing them both money and brand reputation.

We re-engineered their bags with reinforced square-bottom design, multi-ply kraft paper, and moisture-resistant coating. After testing, these bags carried double the weight without tears.

Result? Fewer customer complaints, stronger brand perception, and a 20% drop in packaging waste complaints.

This is why I say—science isn’t just theory. It solves real-world problems.

The Future of High-Strength Paper Bags

So, what’s next? Think smart paper packaging—bags with QR codes that tell recycling instructions. Or bio-enhanced fibers that resist tearing while breaking down faster in compost.

Material science is moving fast. And with AI-powered machinery, predictive quality control, and global sustainability policies, high-strength paper bags are set to become the new global standard.

At GreenWing, we’re not just keeping up—we’re leading. Our 40 patents in bag design and material science are proof.

Conclusion

High-strength paper bags are no longer a “nice-to-have.” They are a necessity, driven by science, sustainability, and customer expectations. And the best part? They prove that being eco-friendly doesn’t mean being weak.