I’ve seen this problem too many times.

Brands invest heavily in products.

But their packaging looks… average.

That’s painful.

Because packaging is the first physical touchpoint.

If it doesn’t speak, it doesn’t sell.

That’s where custom die-cut paper bag designs come in.

They solve sameness.

They create recognition.

And they quietly increase conversions.

Custom die-cut paper bag designs allow brands to create unique shapes, handles, windows, and structural cutouts that elevate visual appeal, improve usability, and strengthen brand identity.

When done right, they reduce material waste, enhance user experience, and make your packaging instantly recognizable on shelves and in customers’ hands.

Still, most buyers underestimate their power.

Let me fix that.

What Are Custom Die-Cut Paper Bag Designs?

Die-cutting is not magic.

It’s precision engineering.

We use custom-made steel dies to cut paper with millimeter accuracy.

This allows us to create shapes scissors can’t.

Think of:

- Custom handles

- Logo-shaped windows

- Special openings

- Structural cutouts

At GreenWing, I treat die-cutting as design + engineering, not decoration.

Why?

Because bad die-cuts tear.

Good die-cuts last.

Why Die-Cut Designs Matter More Than You Think?

Most buyers ask me about price first.

Wrong question.

The right question is:

“What does this bag do for my brand?”

Custom die-cut designs help you:

- Stand out in crowded retail spaces

- Improve carrying comfort

- Reduce extra materials like plastic handles

- Increase perceived product value

According to industry data, consumers are more likely to reuse premium-looking paper bags.

That’s free advertising.

And yes, Mike from the U.S. — your customers notice.

Popular Types of Die-Cut Paper Bag Designs

Not all die-cuts are created equal.

Here are the most effective ones I recommend to B2B buyers.

Die-Cut Handle Bags

No rope.

No patch.

Just clean integration.

Best for:

- Takeaway food

- Fashion retail

- Event giveaways

Window Die-Cut Bags

Customers see the product before opening.

Trust increases instantly.

Common in:

- Food packaging

- Bakery bags

- Gift packaging

Logo-Shaped Cutouts

Subtle.

Premium.

Memorable.

This is branding without shouting.

How Custom Die-Cut Designs Improve User Experience

Let’s talk usability.

Because beauty without function is useless.

A well-designed die-cut:

- Reduces hand pressure

- Balances weight

- Prevents tearing

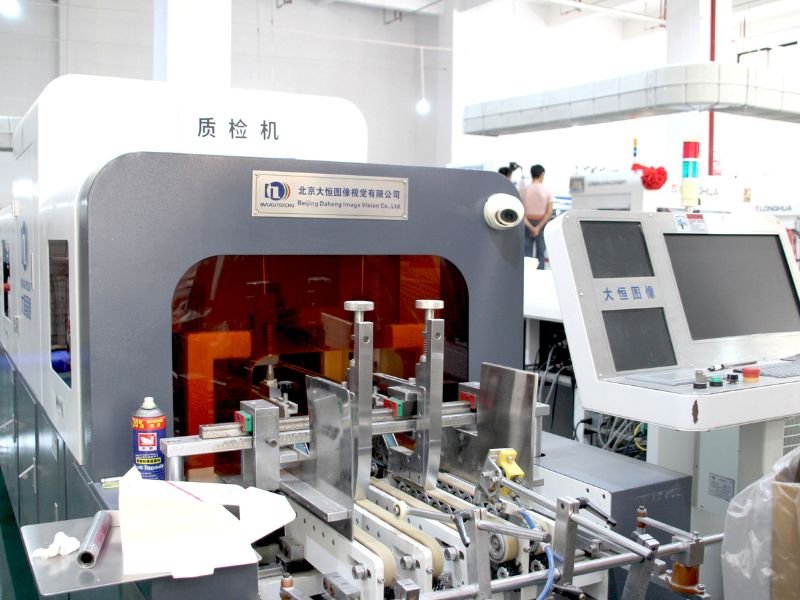

We test this in-house.

Weight load tests.

Drop tests.

Handle stress tests.

According to packaging ergonomics research, poor handle design is a top reason bags fail during use.

I don’t let that happen.

Neither should you.

Material Choices That Work Best for Die-Cutting

Here’s a hard truth.

Not all paper likes being die-cut.

Best materials include:

- High-strength kraft paper

- White kraft with long fibers

- Laminated paper for clean edges

Low-quality recycled paper?

Risky.

Die-cut edges expose paper fibers.

If the material is weak, it tears.

That’s why I always ask buyers about bag weight load before quoting.

Data first.

Design second.

Die-Cut Design vs Traditional Handles: Cost & Value

Let’s talk money.

Yes, die-cut designs can cost slightly more upfront.

But the total packaging cost often goes down.

Why?

- No extra handle materials

- Faster bag assembly

- Reduced logistics volume

According to packaging cost analysis, integrated die-cut handles can lower per-unit handling costs in large volumes.

Smart packaging is not cheap.

It’s efficient.

Common Die-Cut Design Mistakes I See Buyers Make

I’ve seen it all.

And I’d rather you avoid these mistakes.

Top issues include:

- Overly thin handle bridges

- Sharp internal corners

- Ignoring grain direction

- No reinforcement for heavy loads

These mistakes don’t show in mockups.

They show in customer complaints.

My rule?

If it looks cool but fails testing, it’s dead.

How We Customize Die-Cut Paper Bags at GreenWing

Customization is not clicking “add logo.”

It’s a system.

Our process:

- Usage analysis

- Weight load calculation

- Structural design

- Die-line prototyping

- Mass production testing

With 5 million bags daily output, I don’t gamble.

I standardize excellence.

And yes, we provide certifications and inspection reports.

Conclusion

Custom die-cut paper bag designs are not decoration.

They’re strategy.

Done right, they boost branding, usability, and efficiency.

Done wrong, they destroy trust.

If your bag carries your brand,

make sure it carries it well.