Paper bags are everywhere—from coffee shops to luxury retail—but the cost puzzle behind each bag remains a mystery to many buyers.

Importers and distributors often wonder, “Why does one supplier quote me $0.05 per bag, while another charges $0.12?” Without clarity, negotiations feel like shooting in the dark.

Let me pull back the curtain. As the CEO of GreenWing, I’ll show you exactly what goes into the raw material cost of paper bags—so you can make smarter, more confident purchasing decisions.

The cost of a paper bag comes down to four main factors: base paper, coatings & additives, printing & inks, and structural reinforcements. Each has its own price volatility, driven by global pulp supply, chemical markets, and sustainability demands.

Stick with me, and I’ll give you the insider’s breakdown most suppliers won’t share.

Why Focus on Raw Materials?

Raw materials make up 60–70% of the final cost of a paper bag. That means if you understand paper, coatings, and printing, you understand 70% of the pricing game.

Labor, logistics, and machine depreciation matter too, but they’re secondary. For global buyers, knowing the raw material breakdown helps when comparing suppliers across regions—China, India, or Europe.

And trust me—knowing whether a bag uses virgin kraft vs recycled paper could be the difference between paying fair market price or overpaying.

The Base: Paper Types and Their Costs

At the heart of every bag is paper itself. This is where most of the money goes. Here are the main categories:

- Virgin Kraft Paper: Strong, long fibers, high tear resistance. Costs more because it comes directly from wood pulp. Used in premium shopping bags and courier bags. Price: around $800–$1,200 per ton.

- Recycled Paper: Cheaper, eco-friendly, but less strong. Common in grocery bags. Price: $600–$900 per ton depending on grade.

- Bleached/White Kraft: Bright and print-friendly, but requires chemical treatment. Adds 15–20% to cost compared to brown kraft.

- Specialty Food-Grade Paper: FDA-compliant, greaseproof, and heat-resistant. Price premium due to certification costs.

We often blend virgin and recycled fibers to strike the right balance—strength for performance, recycled pulp for sustainability, and competitive pricing.

Additives and Coatings: Hidden But Crucial

Here’s the sneaky part. Paper alone can’t handle oil, water, or hot food. That’s why we add coatings—and yes, they cost money.

- Water-based coatings: Add ~5–8% to material cost. They improve moisture resistance but remain recyclable.

- PLA or Biodegradable Films: Cornstarch-based, used in compostable bags. Adds 20–30% extra to raw material cost.

- Greaseproofing agents: Essential for food packaging. Typically raise costs by 10%.

- Heat-seal layers: Used in courier and food bags. Adds both material and processing costs.

Think of coatings as an insurance policy. They don’t show up visibly, but without them, your “eco-friendly” bag could turn into mush on a rainy day.

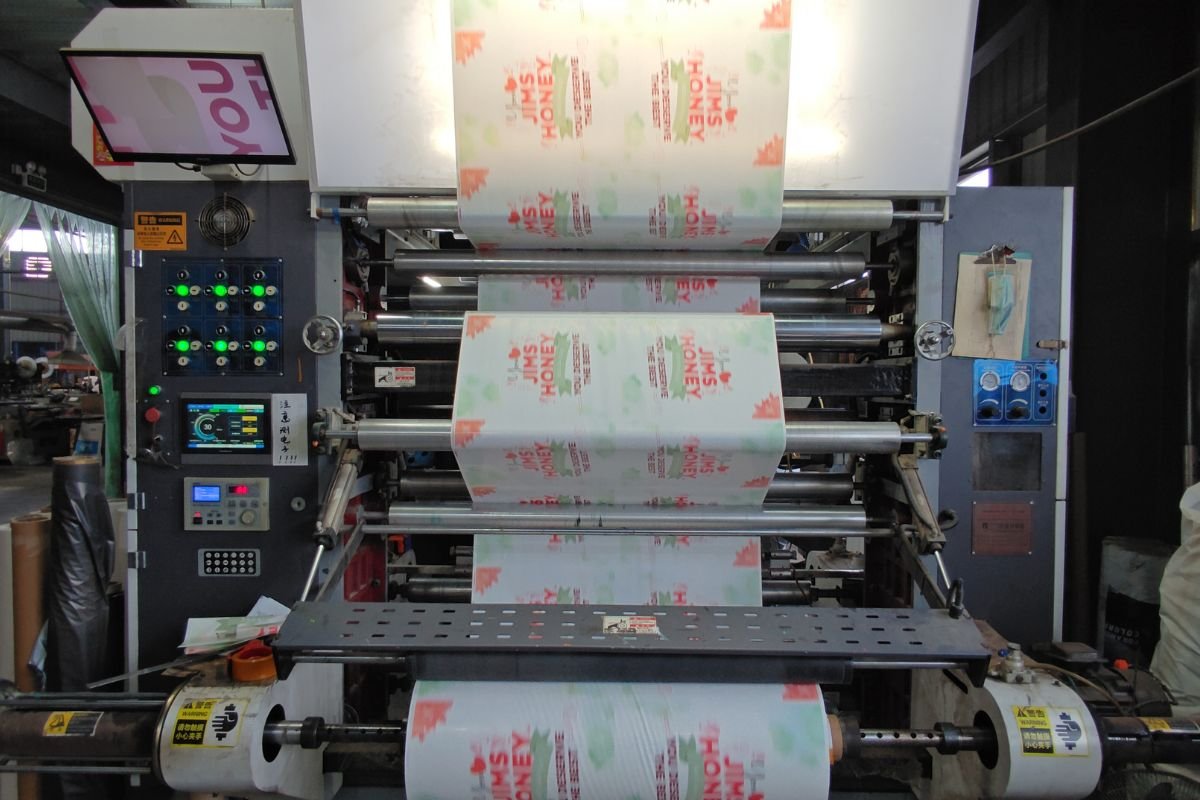

Inks and Printing: Beauty Has a Price

Customers want more than a plain brown bag—they want their logo to pop. That’s where printing costs kick in.

- Water-based inks: Eco-friendly, widely used, cost-effective. Add ~5–10% to raw material cost.

- Soy-based inks: More sustainable, but slightly more expensive.

- Full-surface or multi-color printing: Can increase ink consumption by 20–30%.

We use advanced flexographic and offset printing. Why? Because weak inks can seep into fibers, damaging durability. So yes, premium inks protect both the bag and your brand image.

Handles, Reinforcements, and Glue

Here’s something buyers often overlook: handles and reinforcements are raw materials too.

- Twisted paper handles: Made from the same kraft rolls. Cost-efficient, but add ~0.01–0.02 per bag.

- Flat paper handles: Slightly stronger, slightly pricier.

- Rope or ribbon handles: Popular in luxury bags, add up to 30% extra on raw material costs.

- Bottom & side reinforcements: Cardboard inserts prevent collapsing. They add both material and labor cost.

And yes, even the glue matters. Water-based glues are cheaper; hot-melt adhesives cost more but give extra strength.

Market Forces: Why Prices Fluctuate

Even if the recipe stays the same, raw material costs rise and fall. Why?

- Global pulp supply and demand

- Energy prices (paper production is energy-heavy)

- Transportation costs (importing pulp or recycling streams)

- Environmental regulations (EU bans on single-use plastics push up demand for kraft paper)

For example, when China restricted waste paper imports, recycled pulp prices jumped worldwide. That’s why one month your supplier quotes $900/ton, and the next it’s $1,100.

As a buyer, tracking these trends helps you lock in smarter contracts.

Case Study: Food Packaging Brand

A U.S. food brand once asked us why our quote was 15% higher than a competitor’s. We broke down the costs:

- Virgin kraft for strength (higher base cost)

- FDA-compliant greaseproof coating (adds ~10%)

- Water-based inks for printing

- Reinforced bottoms for heavy meals

When they compared apples to apples, they realized the competitor was offering recycled-only paper with no greaseproofing. Sure, it was cheaper—but also a recipe for bag failure.

Lesson: raw material choices define bag performance. Cheaper isn’t always better.

The Future of Cost Efficiency

Material science is bringing in smarter ways to cut costs without cutting corners. Examples:

- Nanocellulose reinforcement: Less material, same strength.

- Bio-based coatings: Recyclable yet protective.

- AI in production: Reduces wastage of paper rolls and coatings.

We’re constantly balancing cost and performance. Our goal is simple—give customers durability and sustainability at the best possible value.

Conclusion

Raw materials account for most of the cost in paper bags—kraft paper, coatings, inks, handles, and reinforcements all play their part. Prices fluctuate with pulp markets and sustainability regulations, but understanding the breakdown gives you power at the negotiation table.

At GreenWing, we don’t just sell bags—we sell transparency in cost and performance. And in today’s market, that’s worth its weight in kraft paper.