Ever handed a customer a cold drink in a paper bag, only to watch it sag and rip before they’ve taken two steps? Yeah, we’ve been there. Moisture is the paper bag’s arch nemesis — especially in the cold chain and beverage game. But what if I told you that paper bags can fight back?

Yes — with the right materials, coatings, and construction, paper bags can resist condensation and protect your cold products all the way from warehouse to happy customer. These aren’t your typical grocery-store sacks. I’m talking tech-backed, moisture-resistant warriors.

Let me break down how we do it — and how you can win the cold chain battle without compromising on sustainability or style.

Why Is Condensation a Nightmare for Cold Beverage Paper Bags?

Let’s be honest — paper and water have never been best friends. When you’re moving cold or frozen items, condensation is inevitable. That’s just physics.

When warm air hits a cold surface — like a beverage bottle fresh out of the fridge — water droplets form. That moisture soaks into the paper bag unless you do something smart about it. So, what happens?

- Bags weaken and tear

- Ink bleeds, branding fades

- Products fall out (yes, we’ve seen that too)

- Customers complain (and never come back)

In the cold chain logistics world — especially for food brands — failure isn’t just about broken packaging. It’s lost trust, broken brand image, and costly re-shipments.

What Makes a Paper Bag Suitable for Cold Chain Applications?

Let’s talk solutions.

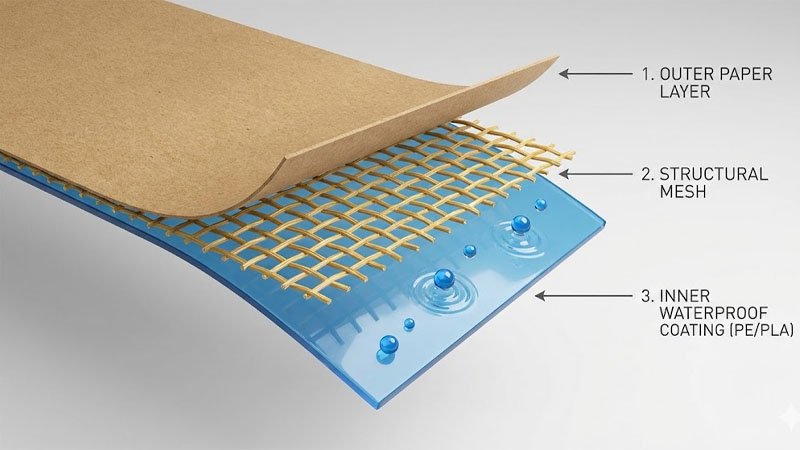

There are three key performance features a cold chain paper bag needs:

- Moisture Barrier: This is your front-line defense. A special coating or laminated layer keeps water droplets on the outside, not soaking in. Think of it like a raincoat for your bag.

- High Wet Strength: We’re not just slapping wax on a bag. We engineer the paper itself to stay strong when wet, using treated fibers and resins. This means no sagging, no tearing.

- Condensation Control: Through smart venting designs or material combinations, we can reduce how much condensation actually sticks to the bag. Magic? Nope — just science and a lot of R&D.

Materials Matter: The Paper Itself Isn’t “Just Paper”

Not all paper is created equal. If you’re buying standard kraft paper bags for frozen items or cold drinks — you’re setting yourself up to fail.

At GreenWing, we use:

- PE-coated kraft paper

- PLA-coated compostable paper (for eco-conscious clients)

- Duplex layer structures for added insulation and strength

Each material is matched to the use case. A bag for frozen dumplings needs different properties than a bag for iced coffee takeaway.

And yes — we can do it with recyclable, compostable, or FSC-certified paper. Because why should sustainability stop at the freezer aisle?

How Customization Solves Moisture Problems for Cold Beverage Brands

Here’s a story.

A client from Canada — a premium cold-pressed juice brand — came to us frustrated. Their gorgeous packaging was getting ruined by condensation. Worse, customers were complaining that bags broke during delivery.

We custom-engineered a solution:

- Moisture-proof inner lining

- Breathable top flap

- Reinforced handles for wet strength

- Special anti-slip texture for easier grip when condensation formed

Problem solved. Sales rose. Customer reviews improved. The juice? Still cold. The brand? Cooler than ever.

The lesson? Don’t settle for generic. The right custom specs solve real problems.

How Cold Chain Distributors Can Prevent Paper Bag Failures During Shipping

If you’re a distributor or importer like Mike Baker (yes Mike, I see you), you know the real headaches start before the customer ever touches the bag.

Cold chain shipping means:

- Long haul, high humidity

- Varying temperatures

- Warehouse delays

- Risk of condensation inside and outside packaging

To handle this, we recommend:

- Double-layer bags: Inner lining protects product, outer layer shows your branding

- Seal-proof closures: To lock in cold air and prevent external moisture invasion

- Low-permeability coatings: To reduce water vapor transmission

And yes — we test all our bags in simulated cold-chain environments. Because if it doesn’t survive the truck ride from Guangdong to California, what’s the point?

Certifications, Compliance, and Customer Peace of Mind

Here’s where many suppliers fail.

They’ll say their bags are moisture-proof and cold-chain ready. But when asked for certifications or testing reports? Radio silence.

At GreenWing, we hold over 40 national patents and 60+ certifications and honors. That includes:

- FSC Certification

- SGS moisture resistance reports

- ISO 22000 for food-grade safety

- REACH compliance for EU-bound goods

Want proof? We provide downloadable compliance documents with every custom order. No more second-guessing. No more risking your brand image on shaky suppliers.

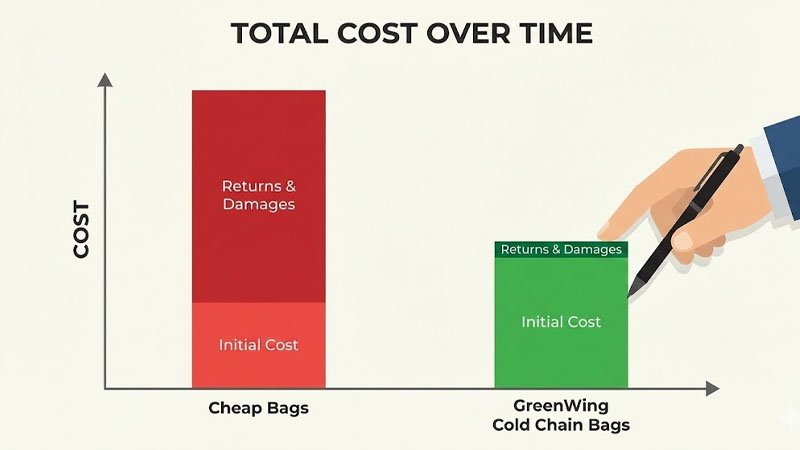

FAQ: Do These Bags Cost More?

Short answer: a little. But long-term? You save money.

Here’s how:

- Fewer returns from damaged packaging

- Better customer satisfaction = higher retention

- Lower replacement and repackaging costs

- Better environmental branding = stronger market position

Plus, with our flexible MOQ and direct-from-factory pricing, you get premium performance without a premium price tag. Talk to us about your target unit price — we’ll make it work.

Conclusion

Moisture doesn’t have to ruin your cold chain packaging.

With the right materials, custom engineering, and a supplier who actually understands your needs — your paper bags can protect cold drinks and frozen goods without compromise.

Let’s keep it cold, dry, and on-brand.