You’re confident in your packaging — until a shipment arrives torn, crushed, or split at the folds. Been there? I have. Your customer gets upset, your product’s damaged, and your brand takes the hit. The weak link? Often, it’s the mechanical properties of the paper bag.

Burst, fold, and tear resistance are the unsung heroes of paper bag performance. Understanding these key properties — and how they’re tested — is critical for quality packaging that survives real-world use.

And no, you don’t need an engineering degree to understand this. I’ll keep it simple — and practical.

What Is Burst Resistance — and Why Does It Matter?

Burst resistance tells us how well a paper bag can withstand pressure before it explodes. (Yes, paper can explode — in a very boring, papery way.)

Technically, it measures the maximum pressure the paper can handle before it ruptures. This is especially important for:

- Heavier loads

- Courier bags

- Multi-wall bags for industrial packaging

If your bag bursts while being handled, that’s not just a failure — that’s a refund waiting to happen.

Fold Resistance — Why It’s the Quiet Strength of a Long-Lasting Bag

Ever noticed how some bags crack along the creases after a few uses?

That’s low fold resistance at work.

Also known as fold endurance, this property tests how many times the paper can be folded back and forth before it breaks. It’s a big deal for:

- Reusable shopping bags

- Takeaway packaging

- Bags with creased or gusseted designs

If your product is meant to last, good fold resistance is non-negotiable.

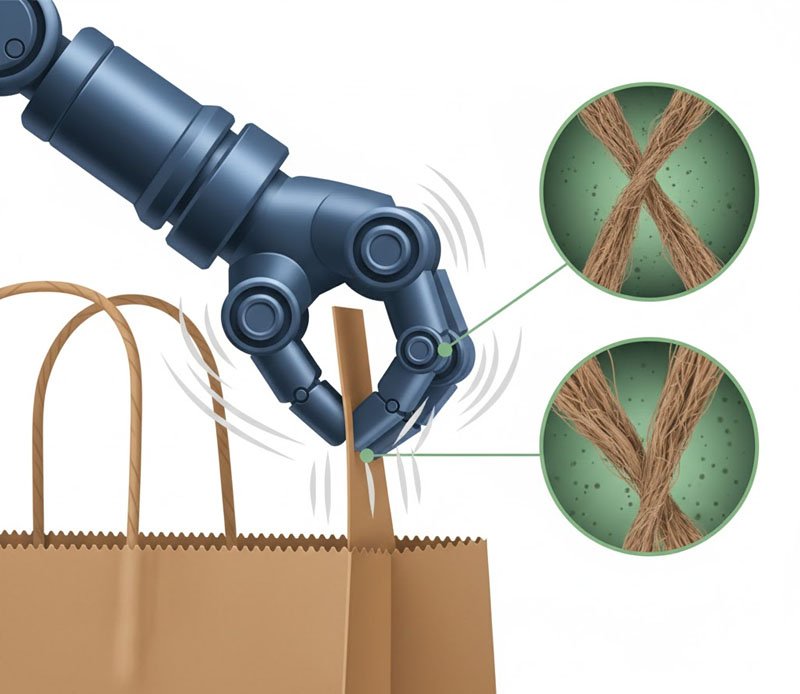

Tear Resistance — The Frontline Against Mishandling

You can have high burst strength and great fold resistance… and still fail if the tear resistance is weak.

Tear resistance measures the paper’s ability to resist propagating a cut or nick. Why does it matter?

Think of someone grabbing a bag from the shelf, snagging it on a corner. If it tears easily — game over.

For:

- Retail bags with die-cut handles

- Courier bags with sharp corners

- Food delivery bags under motion stress

Tear resistance is the frontline defense.

How We Test These at GreenWing (and Why It’s Part of Every Order)

Let me brag a bit.

At GreenWing, every production batch goes through internal quality control. For burst, fold, and tear resistance, we use lab-grade machines — not just eyeballs and guesswork.

- Burst strength testers use a rubber diaphragm to apply uniform pressure

- Fold testers apply automated bending cycles to the paper

- Elmendorf tear testers measure how far a tear spreads from a cut

This isn’t just for show. It ensures our paper bags perform before they ship to you.

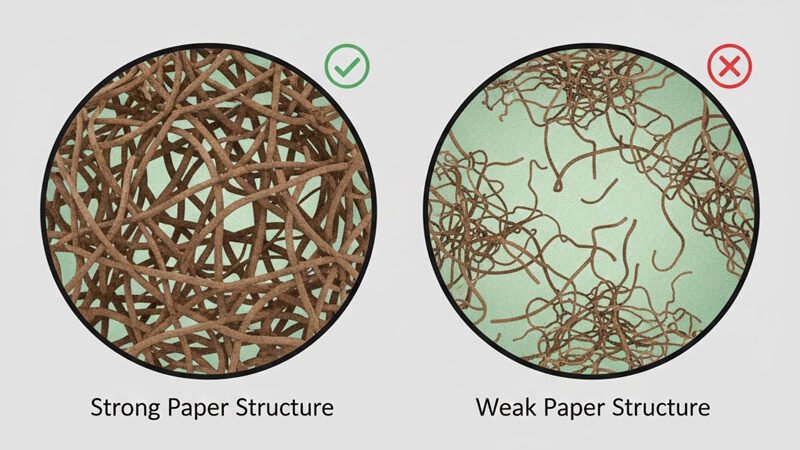

What Influences These Properties? (Spoiler: It’s Not Just Paper Thickness)

People often assume thicker paper = stronger bag.

Not true.

Burst, fold, and tear resistance depend on several variables:

- Fiber length and quality – longer fibers = better strength

- Paper composition – virgin vs recycled matters

- Moisture content – too much or too little can weaken paper

- Coatings and treatments – can affect flexibility and tearing

We use these factors to design the right bag for your use case — not just the thickest one we can sell you.

Which Industries Should Care Most About These Tests?

Every industry benefits from strong packaging, but some live or die by these specs:

- Food delivery: needs fold resistance for heat and moisture

- E-commerce: needs tear resistance for rough handling

- Luxury retail: needs burst resistance for heavier items

- Exporters: need all three — especially if bags face long shipping routes

If you’re in any of these sectors, I’d recommend testing your current supplier’s bags. You might be surprised by what you find.

What Happens When You Skip These Tests?

Short answer? Disasters.

We once had a new client (a fashion brand) who came to us after a batch of paper bags ripped at the handles during a high-traffic store launch. The bags looked beautiful. But they weren’t tested for tear propagation.

Result: customer complaints, social media backlash, and a bruised brand image.

Lesson? Don’t let aesthetics replace performance. We can give you both.

How to Read a Paper Bag Specification Sheet Like a Pro

Okay, now you’re thinking, “Nick, I’m not a scientist.”

You don’t have to be. Here’s what to look for on a spec sheet:

| Property | Minimum Value | Test Method |

|---|---|---|

| Burst strength | ≥ 200 kPa | ISO 2758 |

| Fold endurance | ≥ 20 double folds | ISO 5626 |

| Tear resistance | ≥ 300 mN | ISO 1974 |

Make sure your supplier lists all three, along with the test standard used. If they can’t provide it — that’s your red flag.

Conclusion

Burst, fold, and tear resistance aren’t just lab terms — they’re the backbone of paper bag quality. By understanding these key properties and how to test them, you protect your brand, reduce complaints, and increase customer satisfaction.