Let’s face it — paper bag production used to be slow, labor-intensive, and frankly… a bit boring. But automation? It’s not just speeding things up. It’s flipping the entire game. I’ve watched machines transform what took hours into seconds — and yes, I’m still impressed.

Absolutely, automation is revolutionizing the paper bag industry. From speed and precision to reduced waste and consistent quality, automated systems are redefining how paper bags are made. It’s leaner, cleaner, and a whole lot smarter.

Let’s unpack how this tech is turning our production lines into powerhouses.

Why Is Automation a Big Deal in Paper Bag Manufacturing?

Before automation, our production was like a relay race. Now? It’s Formula One. With over 100 machines humming inside GreenWing’s 50,000 m2 facility, I’ve seen firsthand how automation cuts cost, slashes lead times, and ensures every bag looks like it just came off a Swiss watch line.

Brands want consistency. Buyers like Mike need reliability. Automation delivers both — at scale.

What Kinds of Processes Are Automated?

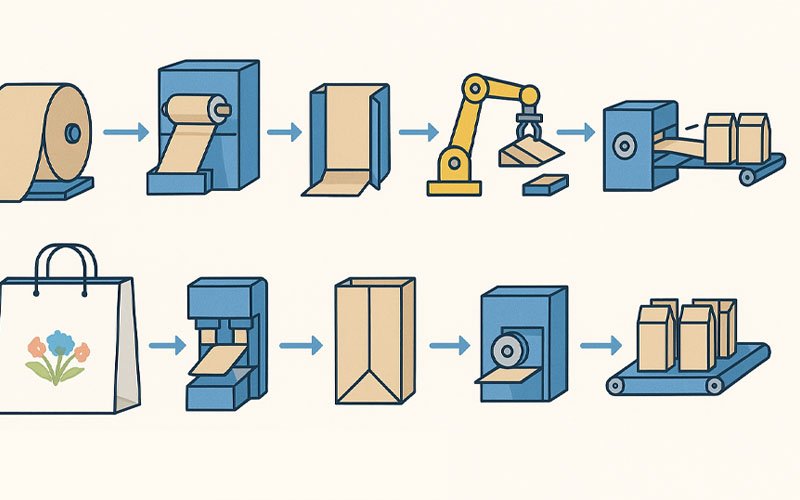

At GreenWing, we’ve automated just about everything that can be:

- Paper Roll Feeding

- Printing (Flexo & Gravure)

- Folding & Gluing

- Handle Attachment

- Bottom Sealing

- Quality Inspection with AI Cameras

- Bag Counting & Packing

This isn’t about replacing people. It’s about letting machines handle the repetition, while our team focuses on design, innovation, and quality control.

Key Benefits of Automation

Why do we invest millions in cutting-edge machinery? Here’s why:

- Precision: Micron-level accuracy every time.

- Speed: 5 million bags daily? Only possible with automation.

- Consistency: Uniform folds, cuts, and gluing.

- Efficiency: Less waste, better material utilization.

- Safety: Fewer manual steps means fewer workplace accidents.

- Scalability: Ramp up production for peak seasons in days, not weeks.

How Automation Helps Mike (Our Buyer Persona)

Mike doesn’t want surprises. He wants 100,000 food bags delivered on time, every time. He wants certification, QC reports, and peace of mind.

Automation helps us:

- Meet tight deadlines

- Pass international quality audits

- Offer real-time production tracking

- Keep product consistency across 50+ SKUs

Automation isn’t just for us — it’s a service to Mike.

What About Custom Orders?

Funny thing — people assume automation kills flexibility. Nope. With the right software and modular machines, we can switch bag sizes, print designs, and handle types in minutes.

That means:

- Faster turnarounds for new designs

- More SKUs with fewer machine reconfigurations

- Real-time adjustments to meet urgent client needs

Whether it’s a flat-bottom food bag or a luxury boutique carrier — we automate and customize.

Quality Control in an Automated Line

We use AI-powered vision systems that scan for:

- Ink smudges

- Misaligned prints

- Faulty folds or glue application

Anything below standard? Auto-rejected.

This keeps our rejection rate under 0.5% — way below industry average. And trust me, when a Starbucks inspector visits your floor, that matters.

Green Gains: Automation and Sustainability

Here’s a fun fact — automation actually makes us greener:

- Optimized material use = less paper waste

- Precision gluing = reduced adhesive usage

- Energy-efficient motors = lower electricity bills

Plus, real-time monitoring means fewer defective bags. That’s eco-friendly, not just cost-friendly.

What’s Next? Smart Automation & AI

We’re already testing:

- Predictive maintenance using machine learning

- Real-time defect prediction

- Self-optimizing production lines

The dream? A factory that adjusts itself to minimize waste, prevent downtime, and deliver 24/7 without compromise.

Conclusion

Automation isn’t a future trend. It’s the present backbone of every competitive paper bag manufacturer. At GreenWing, it powers everything we do — so you can rely on every bag, every time.