Your packaging looks great — until someone touches it with a wet hand or sets it on a greasy counter. Suddenly, that “premium feel” takes a nosedive. Frustrating, right? We’ve been there.

Yes, custom coatings are the secret sauce. They’re like invisible bodyguards for your paper bags — protecting against moisture, grease, and scuffs while enhancing the print, texture, and customer experience. From matte finishes to anti-slip coatings, custom coatings do more than just shine — they work.

And if you think coatings are one-size-fits-all, buckle up. There’s a whole world beneath that glossy surface.

What Exactly Are Custom Coatings for Paper Bags?

Let me put it simply — coatings are ultra-thin layers applied to the surface of a paper bag to protect it or give it some visual flair.

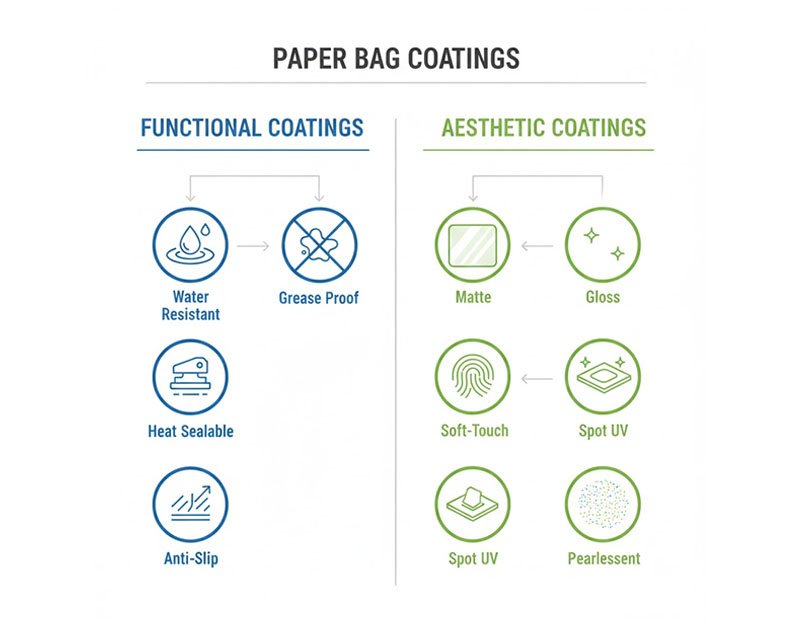

There are two major types: functional coatings and aesthetic coatings.

Functional ones include grease-proof, water-resistant, or heat-sealable coatings. Perfect for our food industry clients — yes, I’m looking at you.

Aesthetic ones? That’s where the visual magic happens. Think soft-touch matte, UV spot gloss, or even pearlescent shimmer. All applied to enhance the brand image without compromising recyclability (yep, we keep it green).

Why Are They So Important?

In one word? Protection.

Let’s say your bag is used to package a hot sandwich. No coating? Say hello to oil stains and a bag that looks like it ran a marathon.

Add a grease-resistant coating? Boom — brand integrity intact.

Also, let’s talk logistics. Coatings can make bags more resistant to humidity during shipping or warehouse storage. Less damage, fewer complaints.

Plus, they boost print quality. That logo you paid a designer $5,000 for? It deserves to shine — or stay matte — without smudging.

Can You Still Recycle a Coated Paper Bag?

This is the million-dollar question.

Answer: It depends on the coating.

Some traditional plastic lamination makes recycling difficult, yes. But at GreenWing, we use eco-friendly water-based coatings and biodegradable options that pass recyclability tests in the U.S., EU, and Australia. No greenwashing here.

We even hold certifications for it.

So yes, coatings can be green — if you partner with a factory that actually knows what it’s doing.

What Kinds of Custom Coatings Can I Choose From?

I’m glad you asked. Here’s a sample menu from our customization buffet:

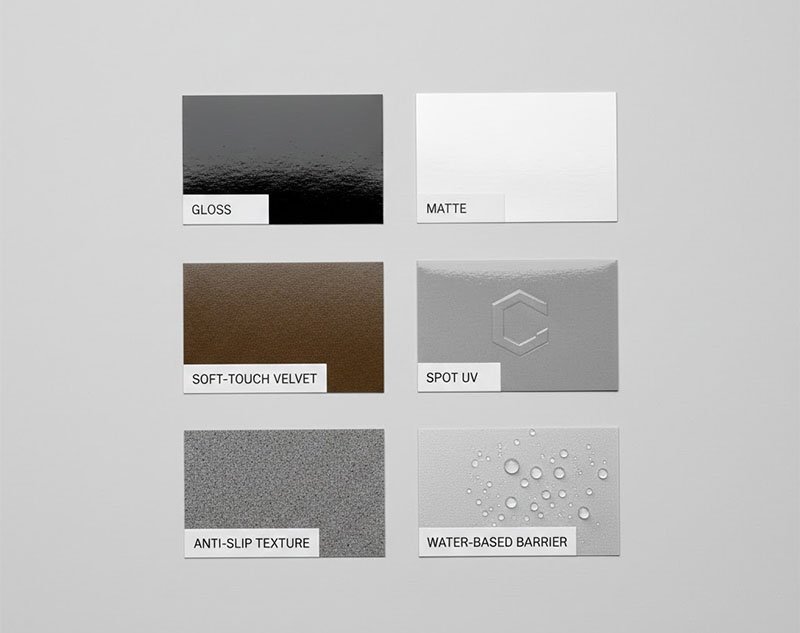

- Gloss Coating – Makes colors pop. Adds a sleek, modern look.

- Matte Coating – Smooth, non-reflective finish. Think luxury branding.

- Anti-Slip Coating – Especially good for stacking bags or machine handling.

- Grease-Proof Coating – For food packaging. Keeps the bag neat.

- Water-Based Barrier Coating – Repels moisture without plastic.

- UV Coating / Spot Gloss – Highlights specific areas (like logos) for contrast.

- Soft-Touch Coating – Velvet-feel texture. Makes customers go “Ooooh.”

Each one serves a different purpose. And yes, we help you choose based on your products, not just what’s trendy.

Do Coatings Affect Price?

A little, but not as much as you think.

For most of our B2B clients, the price bump per bag is minimal — we’re talking fractions of a cent — but the perceived value goes way up.

Let me ask: if a $0.03 coating can prevent a bag from failing during delivery, isn’t that a good investment?

Also, applying coatings in-house, like we do at our 50,000 m² facility, means you avoid third-party markups. You’re getting factory-direct efficiency.

Do Coated Bags Work for Takeaway and E-Commerce Packaging?

Absolutely.

For takeaway food, coatings like greaseproof and heat sealable types are critical. They protect the contents and your brand image. A soggy bottom? Not on our watch.

For e-commerce, matte or anti-scratch coatings help the bags survive rough logistics handling — think Amazon warehouses or postal sorting machines.

We’ve even developed anti-counterfeit coating patterns for big clients like JD and RELX.

More Related Questions

Can I Print Over Coatings?

Yes, and it looks amazing — if done right.

We use advanced flexo and gravure machines that print cleanly on coated surfaces. And we always do ink adhesion tests beforehand. No flaking, no fading.

Will Coatings Add to Lead Time?

Only slightly. If the coating is part of the inline production (as ours is), lead time increases by 1-2 days max. Totally worth it for the results.

Are Coatings Safe for Food Contact?

Yes, if they’re food-grade.

We source coatings compliant with FDA, EU, and GB standards. Always happy to send certification copies — no surprises here.

Can You Mix and Match Coatings?

Heck yes.

We’ve done bags with matte body + gloss logo. Or soft-touch feel + water resistance. Custom is literally in our name.

Talk to us about your idea, and we’ll prototype it.

Conclusion

Custom coatings aren’t just about looking good — they perform. From protecting your products to elevating your brand, the right coating gives your bag superpowers. We know exactly how to tailor them to your needs — without busting your budget.