Plastic coatings have had their time in the spotlight — and honestly, their time is up. They’ve helped paper bags resist grease, moisture, and oil, but they also made them nearly impossible to recycle or compost. That’s where biodegradable coatings step in — the smart upgrade for sustainable packaging.

Biodegradable coatings provide all the protective benefits of plastic or PE layers but naturally decompose after use. They make paper bags truly eco-friendly, recyclable, and compostable without sacrificing durability or print quality.

I’ve spent years in packaging manufacturing, and I can confidently say: this is the future of sustainable packaging design.

What Are Biodegradable Coatings Made Of?

Let’s start with the basics. Biodegradable coatings are thin layers applied to the surface of paper bags to improve water and grease resistance. Unlike traditional plastic coatings, they’re made from natural, renewable materials like:

- PLA (Polylactic Acid): derived from corn starch or sugarcane

- PHA (Polyhydroxyalkanoates): produced by microbial fermentation

- Water-based polymers: biodegradable and VOC-free

- Plant-based waxes and starch blends

These coatings act as a protective shield without blocking recyclability. Once discarded, they break down under composting conditions within 90–180 days.

What I love most about these materials is their circularity — made from nature, returned to nature.

Why Traditional Coatings Are Failing the Environment

Most “paper” packaging you see in stores isn’t as green as it looks. A glossy sandwich bag or coffee cup often has a PE (polyethylene) layer. That thin plastic film makes it waterproof — but also unrecyclable.

According to, over 8 million tons of PE-coated paper waste end up in landfills annually. Recycling plants can’t process it, and composting facilities reject it because plastic doesn’t decompose.

I’ve seen many brands proudly claim “eco paper,” yet their packaging still uses PE coatings. It’s like wearing a raincoat made of plastic wrap and calling it breathable. Consumers are catching on — and they want authenticity, not greenwashing.

Biodegradable coatings solve that dilemma. They give paper the same protective functionality but keep it truly compostable.

How Biodegradable Coatings Work on Paper Bags

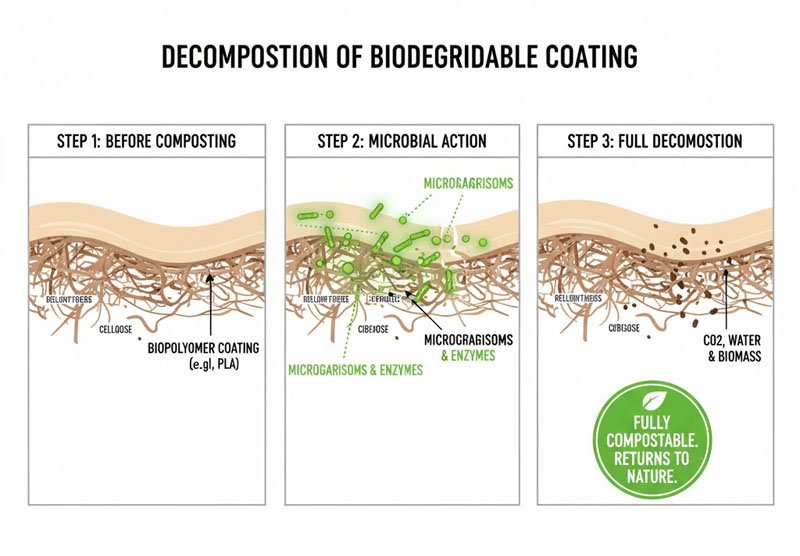

Here’s where the science gets interesting. When we apply a biodegradable coating to paper, it forms a micro-layer that binds to cellulose fibers. This creates a smooth, oil-resistant surface that prevents moisture from seeping through.

Depending on the formula, we can customize coating performance — for grease resistance (for food), moisture barrier (for cold drinks), or printability (for branded retail bags).

At GreenWing, we use water-based dispersion coatings that are both heat-sealable and compostable. They can replace PE lamination in flat-bottom, square-bottom, or takeaway food bags without compromising flexibility.

When disposed of, microorganisms in soil or compost environments break the coating down into CO₂, water, and biomass. No toxins. No microplastics.

This is what I call “clean protection with a conscience.”

Market Trends: Who’s Switching to Biodegradable Coatings?

It’s not just startups anymore. Major brands are making the switch. The food and beverage industry leads the pack — coffee shops, bakeries, and quick-service restaurants are replacing PE-coated cups and bags with biodegradable alternatives.

A report estimates the global biodegradable coating market will exceed $5 billion by 2032, growing at 6.5% CAGR. The drivers? Environmental regulations, consumer demand, and retailer pressure.

Countries like the U.S., Canada, and members of the EU are tightening single-use plastic bans. Retailers are also demanding packaging that meets compostability certifications (EN 13432, ASTM D6400).

When brands switch, they don’t just reduce waste—they gain an instant marketing edge. Eco-friendly packaging isn’t just about compliance anymore; it’s a statement of responsibility.

As I like to say, “Your bag talks before your brand does.”

Manufacturing Challenges and How We Solved Them

Of course, innovation isn’t without hurdles. Early biodegradable coatings were sticky, hard to print on, or too expensive for large-scale use.

At GreenWing, we’ve spent years refining the process. Our R&D team developed a low-cost, high-performance starch-polymer blend that performs like PE but runs smoothly on existing automatic bag-making machines.

We’ve also solved the heat-sealing issue, one of the biggest headaches in biodegradable packaging. Our coatings can seal at temperatures as low as 110°C, saving energy and improving production efficiency.

Printing? Not a problem. We use soy-based inks compatible with our coatings to maintain vivid colors without smudging.

So, whether it’s a boutique food brand or a massive retail chain, we can scale eco-friendly coatings without trade-offs.

Environmental Impact: Measuring the Real Benefits

The difference between “eco-friendly” and “truly sustainable” comes down to measurable results.

Here’s what the data says:

- Biodegradable coatings can reduce carbon footprint by up to 40% compared to PE laminates.

- Compostable coatings degrade completely within 6 months in industrial composting.

- Energy consumption during production is 20–30% lower due to shorter curing times.

Plus, since coated paper bags are fully recyclable, brands can close the loop through fiber recovery—turning used bags into new paper products.

Imagine your coffee bag becoming part of a notebook or a takeaway box in its next life. That’s circular design in action.

For customers like Mike Baker, who care deeply about certifications and logistics, biodegradable coatings eliminate recycling concerns and simplify compliance paperwork. Less red tape, more green reputation.

Why GreenWing Is Leading the Change

We’ve been manufacturing paper bags since 2008, and innovation is in our DNA. Our 50,000 m² production facility runs with over 100 advanced machines, and we produce 5 million bags daily—now, increasingly coated with biodegradable materials.

What sets us apart is our one-stop customization service:

- R&D formulation and coating selection

- High-speed automatic production

- Flexo or offset printing up to 8 colors

- Global logistics and certification support

Every bag that leaves our facility represents not just packaging—but a promise: that sustainability and performance can go hand in hand.

When a brand chooses GreenWing’s biodegradable coatings, they’re not just buying bags. They’re investing in a cleaner planet, and frankly, a smarter business future.

More Related Questions

Are biodegradable coatings food-safe?

Absolutely. All our coatings comply with FDA and EU food-contact safety standards. Perfect for direct contact with bread, coffee, or takeaway meals.

Can biodegradable-coated paper be printed and heat-sealed?

Yes! Our coatings support heat sealing, die-cutting, and multi-color printing—ideal for branded packaging.

What’s the cost difference compared to PE coatings?

Slightly higher, about 10–15% more per unit, but offset by eco tax savings and stronger consumer appeal.

Are these coatings suitable for cold or oily foods?

Definitely. Our starch-polymer and wax hybrid coatings perform exceptionally well against oil and moisture, ideal for fast food or bakery packaging.

Conclusion

Biodegradable coatings are transforming paper bags from “eco-friendly-looking” to genuinely sustainable. They protect food, meet global green standards, and keep your brand future-ready.

At GreenWing, we’re proud to be part of that revolution—creating packaging that looks good, performs better, and leaves no trace behind.

Because the best coating isn’t just protective—it’s responsible.