Tired of hearing customers complain about ripped handles or soggy bottoms? We’ve all been there. Nothing ruins a good brand impression faster than a weak paper bag. And in my 15 years running GreenWing, I’ve learned one truth: durability isn’t optional—it’s expected.

To increase bag durability, we use reinforcement techniques like patching handle areas, laminated linings, cross-bottom folds, gussets, and heavier GSM paper. Each technique adds strength without compromising flexibility, and most importantly—they keep your product safe until it reaches your customer.

But let’s not stop at the surface. I’ll show you the tricks we use to make millions of tough, tear-proof bags every single day.

Why Does Bag Durability Matter So Much?

Let’s say Mike (yes, you, our favorite food brand guy in the U.S.) is delivering hot meals in branded paper bags. If that handle snaps? It’s not just a mess. It’s a brand failure.

Stronger bags prevent:

- Spills

- Product loss

- Bad reviews

- Lost trust

When a customer trusts your packaging, they trust your brand. So yes, every layer counts.

1. Reinforced Handle Areas

Here’s the #1 failure point in most paper bags: the handle joint.

To stop that:

- We use paper patches—extra pieces glued inside the bag where handles attach.

- For rope handles, flat paper strips work great.

- For twisted handles, we double-patch.

These techniques increase carry weight by up to 50%—and prevent the dreaded “rip heard round the world.”

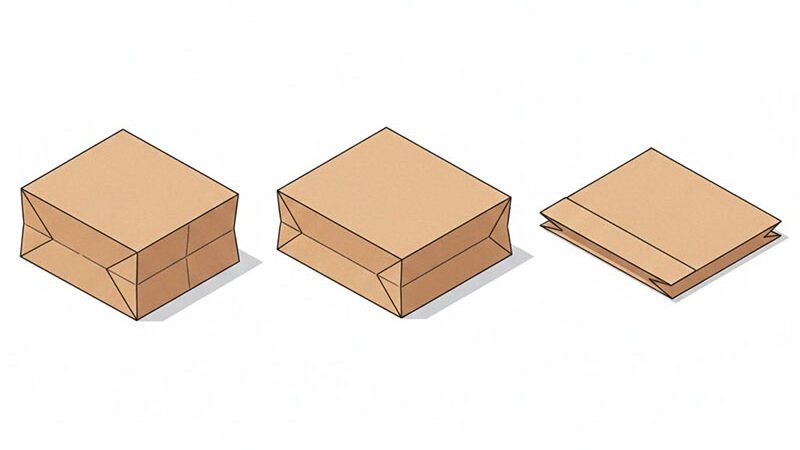

2. Cross Bottoms and Block Bottoms

Flat-bottom bags? Easy to fold, but don’t stand up well under pressure.

That’s why we build many of our bags with:

- Cross bottoms (X-folds) for better load distribution

- Block bottoms for takeout, bakery, and retail bags—they sit flat, stack well, and resist tearing.

Both designs reduce stress concentration at the bottom edges, which is where cheap bags usually give up first.

3. Laminated or Coated Interiors

Here’s a trick from the pros: lamination doesn’t just make things shiny. It makes bags tougher.

- PE lamination prevents grease and moisture from weakening the paper.

- PLA coating (for eco versions) resists humidity while remaining compostable.

These inner coatings are game changers for food packaging. No more soggy bottoms.

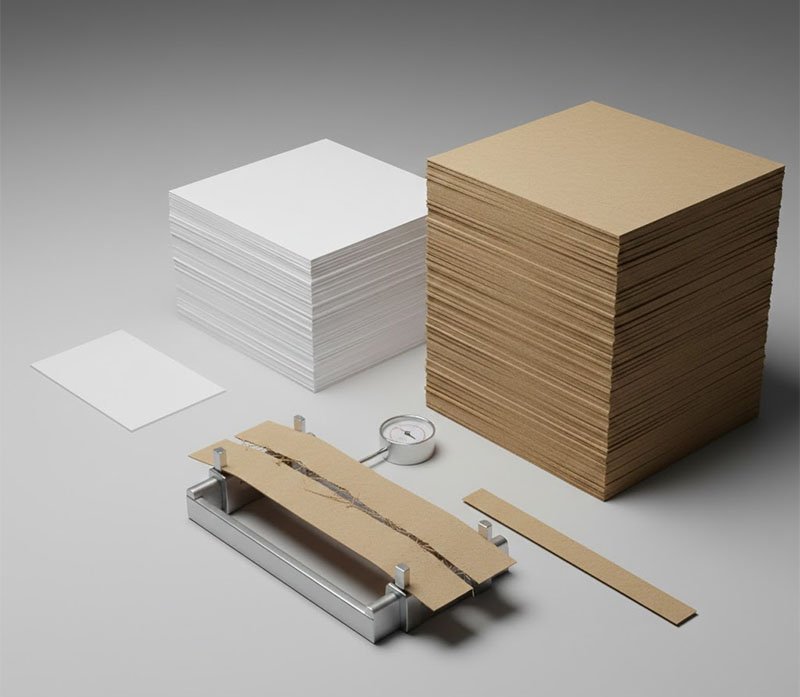

4. Heavier GSM Paper

Not all paper is created equal. Thickness matters.

Standard regular paper is about 60–80gsm. For serious durability:

- Kraft 100–150gsm is our daily driver.

- Courier bags go up to 200gsm or more.

Higher GSM = more fiber = more strength. It’s basic physics (and basic packaging sense).

5. Gussets for Flexibility & Strength

Ever tried stuffing a burger box into a flat bag?

Side gussets expand the bag’s width, letting it flex and hold odd-shaped items. The pressure gets distributed across folds—not one weak seam.

Bonus: gussets make bags easier to stack, store, and carry.

6. Double Gluing & Strong Adhesives

Let me confess something. We’re glue nerds over here at GreenWing.

- Our machines use hot melt adhesives that bond instantly and strongly.

- We apply double glue strips at high-stress zones (especially base folds).

Cheaper factories skip this to save costs. We don’t. And it shows.

7. String Reinforcements (For Courier or Specialty Bags)

When we make courier or e-commerce bags, sometimes paper alone isn’t enough.

We embed cotton strings or synthetic threads into seams for ultra-high load capacity. Think 10+ kg carry weights. This works especially well for:

- Wine bags

- Industrial packaging

- High-value retail items

Not pretty—but effective as heck.

More Related Questions

Can these reinforcements be used on eco-friendly bags?

Yes. We use FSC-certified kraft, water-based inks, and even PLA lamination. Durable doesn’t have to mean dirty.

Will reinforced bags cost more?

A bit. But compare that to the cost of customer complaints, repackaging, or refunds. Reinforcement pays for itself.

How do I know what reinforcement I need?

That’s what we’re here for. At GreenWing, we do full needs analysis—product weight, use case, climate, logistics—and suggest the right structure.

Can I get strong bags and fancy printing?

Absolutely. Our printing tech handles:

- Foil stamping

- CMYK flexo

- Matte/gloss coatings All without compromising the strength of the bag. Looks good. Works better.

Conclusion

Durability doesn’t happen by accident. It’s a combo of clever design, strong materials, and expert manufacturing. Whether you’re packing hot food or high-end retail, the right reinforcements keep your product—and your reputation—safe.