Struggling with torn bags, weak packaging, or unhappy customers? You’re not alone. Many brands rely on paper materials, only to find that some simply don’t hold up under pressure. Weak packaging hurts your product—and your reputation.

Kraft paper is significantly more durable than regular paper due to its stronger fibers, higher tear resistance, and manufacturing process. It’s the go-to for brands that need strength and reliability, especially in packaging. Regular paper, on the other hand, is cheaper but much weaker when put to the test.

So what really sets Kraft apart? Let’s break it down, from fiber to finish.

What is Kraft Paper, Really?

Kraft paper isn’t a fancy term. It’s a workhorse.

It’s made using the Kraft process—a chemical pulping method that keeps the cellulose fibers long and strong. That’s the key. The result? A paper that’s thicker, tougher, and able to handle rough handling.

Brown Kraft paper, white bleached Kraft, and coated Kraft are all variations. We use them all here at GreenWing, depending on the customer’s need.

How is Regular Paper Made?

Regular paper (the kind used in notebooks, flyers, or cheap bags) is usually made through mechanical pulping or recycled pulp methods.

That means shorter fibers, lower strength, and a smoother—but weaker—finish. You can spot the difference by feel. Regular paper crumples easily. Kraft resists.

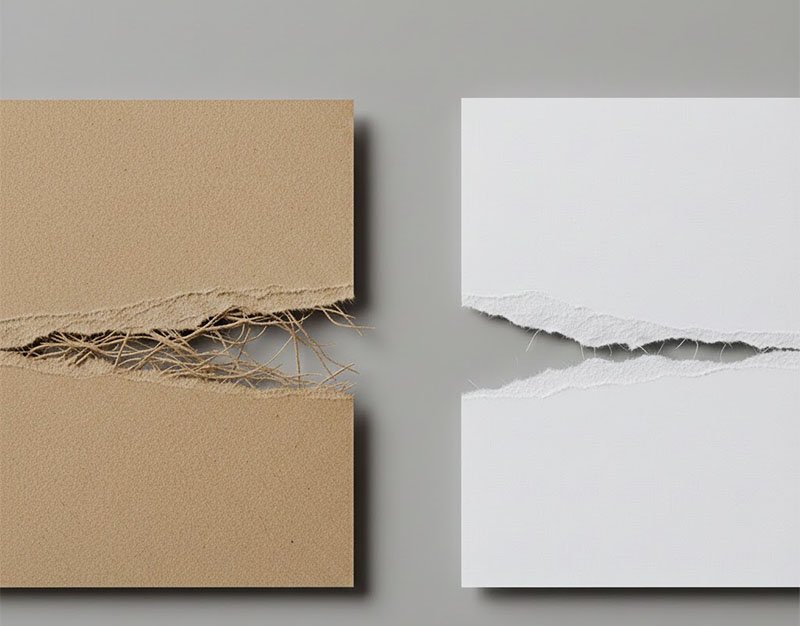

Tear Resistance: Who Wins?

We’ve put both materials through internal tear tests. Kraft paper wins. Every. Single. Time.

Kraft paper has up to 4x higher tear resistance compared to standard office paper or low-grade recycled paper. That’s not just lab stuff. We hear it from our customers daily.

A takeaway bag made from regular paper might survive a donut. But a box of fries? Forget it.

Wet Strength: Can It Handle Moisture?

Ever had a paper bag fall apart on a rainy day? That’s moisture doing its thing.

Kraft paper—especially food-grade or coated versions—can resist moisture better. We even offer wet-strength kraft paper that holds up in humid, greasy, or cold environments. Great for frozen foods or oily snacks.

Regular paper? No chance. Once it’s wet, it’s game over.

Load-Bearing Capacity: Bag Break Test

Here’s a simple test: Put five apples in both a kraft paper bag and a regular paper bag.

The kraft bag holds. The regular one… you’ll be sweeping fruit off the floor.

Kraft paper’s tensile strength—its ability to stretch without tearing—makes it ideal for handheld bags, courier packaging, or anything bulky.

Eco-Friendliness: Is Kraft Still Green?

Some people think “stronger” means “less eco-friendly.” Nope.

Kraft paper is 100% recyclable, biodegradable, and can even be composted (depending on coatings). At GreenWing, we use FSC-certified kraft paper from responsibly managed forests.

Regular paper can be recycled too—but not if it tears apart mid-use. Durability increases lifecycle value. That’s why stronger paper can be more sustainable.

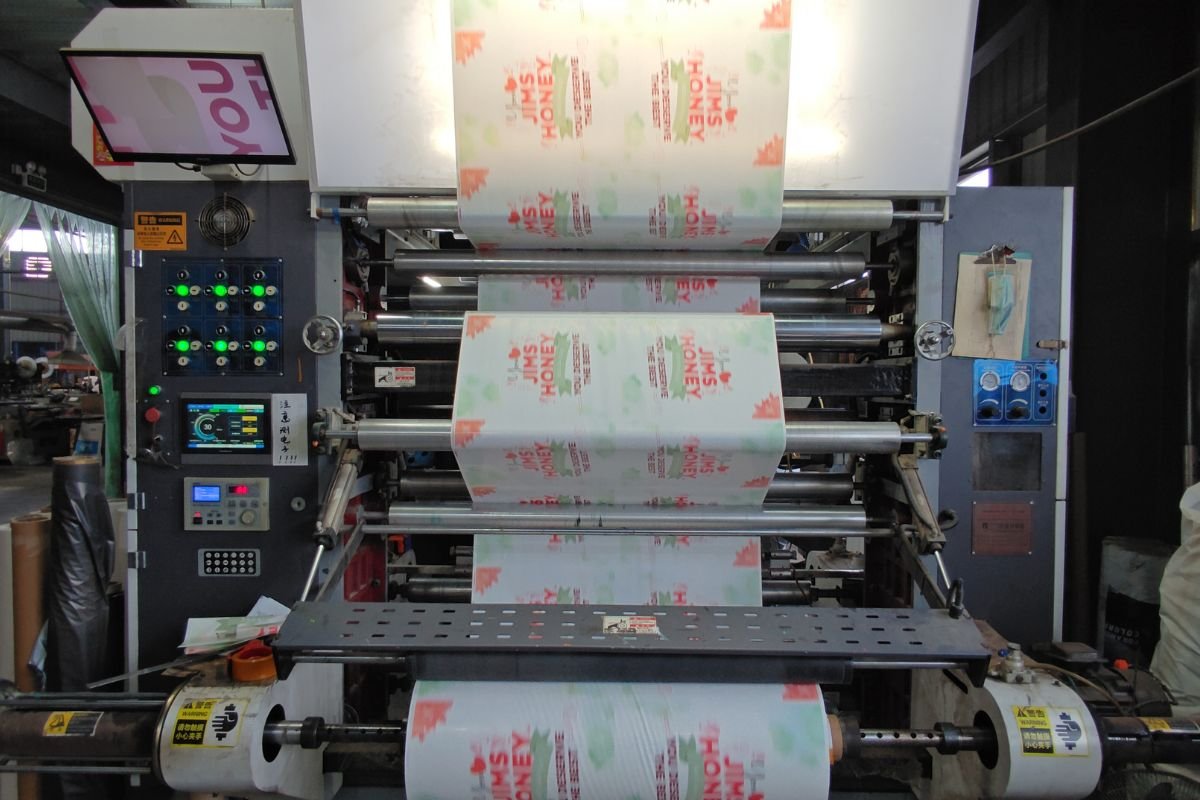

Printing & Customization: Does Durability Affect Design?

You bet.

Kraft paper is durable, but also print-friendly—especially with modern printing tech. At GreenWing, we use flexo and water-based ink systems that bond well with the kraft surface.

Want gold foil, UV gloss, or embossed branding? Kraft handles post-processing better. Regular paper tends to wrinkle, warp, or fade.

When Should You Use Regular Paper?

I’m not saying regular paper is useless.

It’s fine for inner linings, protective sheets, or low-stress printing. If you’re handing out leaflets or need a paper that folds easily, sure—use regular stock.

But for food packaging, e-commerce mailers, or anything people carry in hand? Kraft’s your best friend.

More Related Questions

Is kraft paper more expensive?

Yes—but not by much. Especially when you consider fewer product failures, stronger branding, and higher customer satisfaction. You save more long-term.

Can kraft paper be customized?

Absolutely. We offer full customization—sizes, handles, finishes, you name it. That’s one of GreenWing’s biggest advantages.

Is bleached kraft paper weaker?

Slightly. Bleaching softens the fiber a bit. But modern methods keep most of the strength intact. Many brands use white kraft for premium looks with good durability.

What’s the best kraft paper GSM for packaging?

Depends on what you’re packing. For food bags: 80–100gsm. For courier and retail: 120–150gsm. We consult with every client based on their exact needs.

Conclusion

If you want strength, reliability, and a better customer experience—go kraft. Regular paper has its place, but not in high-stress packaging. That’s why we’ve made kraft our go-to material at GreenWing.