I see this mistake all the time.

Brands spend money on beautiful paper bags.

Then they throw products inside like loose change.

That causes damage.

Confusion.

And unhappy customers.

Packaging is not just the outside.

The inside matters just as much.

Custom inserts and dividers inside paper bags are designed to separate, protect, and organize products while enhancing unboxing experience and brand perception.

They reduce breakage, improve logistics efficiency, and help brands present products in a more premium, structured way—especially in food, retail, and gift packaging.

If your bag looks great but fails inside, you’re leaking money.

Let me explain why.

What Are Custom Inserts and Dividers in Paper Bags?

Let’s get clear first.

No buzzwords.

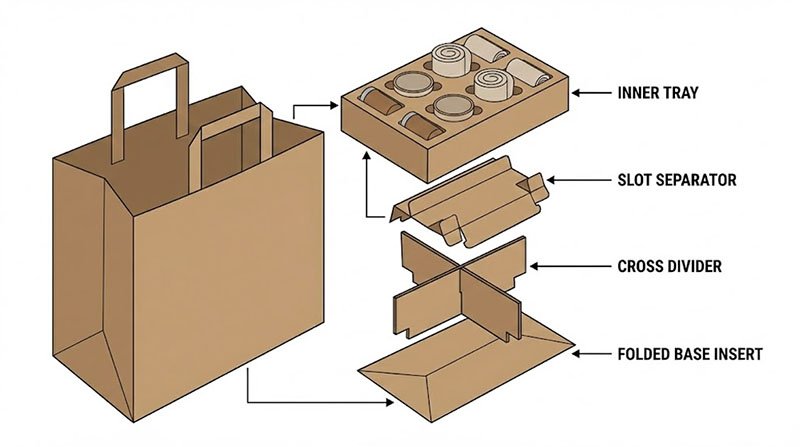

Inserts and dividers are internal paper structures placed inside bags.

Their job is simple:

Hold products in place.

They can be:

- Folded paper inserts

- Cross dividers

- Slot-style separators

- Full inner trays

We custom-make them based on product size, weight, and quantity.

No guessing.

At GreenWing, I see inserts as hidden engineers.

You don’t notice them—until they’re missing.

Why Inserts and Dividers Are Critical for Product Protection

Damage costs money.

Returns cost more.

Without inserts, products:

- Knock into each other

- Tilt during transport

- Tear bag bottoms

- Leak, crack, or deform

According to packaging damage statistics, internal separation can reduce transit damage significantly.

This is especially critical for:

- Glass bottles

- Food containers

- Cosmetics

- Electronics accessories

A bag that protects is a bag that sells again.

Common Types of Paper Bag Inserts and Dividers

There is no “one-size-fits-all.”

If a supplier says that, run.

Here are the most common types we produce.

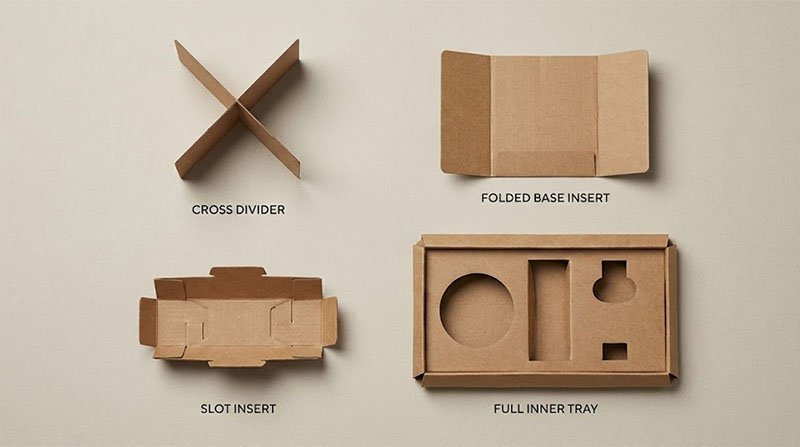

Cross Dividers

Perfect for bottles and jars.

Keeps items upright and separated.

Folded Base Inserts

Reinforce the bottom.

Increase load-bearing strength.

Slot Inserts

Great for food boxes or cosmetics.

Easy assembly.

Full Inner Trays

Premium feel.

Maximum stability.

Each type has a different cost, strength, and assembly speed.

We balance all three.

How Inserts Improve User Experience (Not Just Protection)

This is where smart brands win.

When customers open the bag and see:

- Neatly aligned products

- Clear separation

- No mess

They feel control.

And confidence.

User experience research shows organized packaging increases perceived product value.

That’s psychology.

Not printing.

I always say:

Chaos inside the bag = chaos in the brand.

Best Materials for Inserts and Dividers

Material choice matters more than people think.

For inserts, we typically use:

- High-density kraft paper

- Corrugated paperboard

- Food-grade white card

- Laminated paper for moisture resistance

Thin paper saves pennies.

Then costs dollars in complaints.

Material strength testing proves higher GSM inserts significantly improve load stability.

I design inserts like furniture.

Structure first.

Decoration later.

Inserts and Dividers for Food Packaging Paper Bags

Food brands, listen closely.

Food bags without inserts are accidents waiting to happen.

Common use cases:

- Takeaway meals with multiple containers

- Bakery items

- Beverage + food combos

Inserts prevent:

- Sauce spills

- Heat damage

- Cross-contamination

Food packaging compliance also requires proper separation in many markets.

Smart inserts protect products.

Smarter ones protect brands legally.

Cost Considerations: Are Inserts Worth the Investment?

Short answer?

Yes.

Long answer?

Let’s talk numbers.

Inserts slightly increase unit cost.

But they reduce:

- Damage rate

- Customer complaints

- Refunds

- Secondary packaging needs

Packaging cost analysis shows internal packaging often lowers overall supply chain costs.

Cheap packaging is expensive.

Good packaging pays rent.

![cost vs value packaging chart]

Common Mistakes Buyers Make with Inserts and Dividers

I see these weekly.

And they hurt.

Top mistakes:

- Overcomplicated designs

- Ignoring assembly time

- Weak locking structures

- Mismatch with bag size

The worst mistake?

Designing inserts without testing real products.

We prototype.

We test.

We drop bags.

Pretty diagrams don’t survive logistics.

How We Customize Inserts and Dividers

Here’s how we do it.

No shortcuts.

Our process:

- Product dimension analysis

- Weight and stacking evaluation

- Insert structural design

- Prototype testing

- Mass production optimization

With 5 million bags per day, mistakes scale fast.

That’s why we engineer before we print.

We also provide inspection reports and certifications .

If the inside works, the outside shines.

Conclusion

Custom inserts and dividers turn paper bags into systems.

They protect products.

They improve experience.

They reduce costs.

If your packaging carries value,

make sure it carries it safely—inside and out.