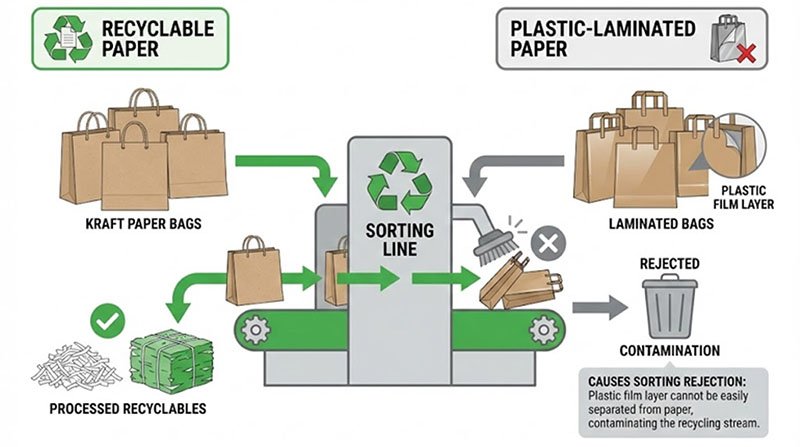

Plastic-laminated paper bags used to be the gold standard—until customers started side-eyeing anything that didn’t scream “eco.” The problem? Traditional PE lamination isn’t recyclable, isn’t compostable, and let’s be honest—it’s not winning any sustainability awards anytime soon.

Luckily, the packaging world is evolving, and today we’ve got three solid alternatives: starch-based coatings, polyvinyl alcohol (PVOH), and water-based coatings. Each has its pros and cons, and choosing the right one really depends on your needs.

So, what’s the best choice for your business? Let me walk you through it.

Why Replace Plastic Lamination in Paper Bags?

It’s no secret: PE (polyethylene) lamination clogs up recycling systems and adds to landfill waste. And with the growing demand for sustainable packaging solutions, businesses are under pressure to switch to greener alternatives.

At GreenWing, I’ve been working with importers, brand manufacturers, and distributors who are tired of hearing “your bags can’t be recycled.” So we’re making the shift—together.

Replacing PE lamination isn’t just about being green. It’s about future-proofing your brand, appealing to eco-conscious consumers, and staying ahead of upcoming regulations.

What Are Starch-Based Coatings?

Starch-based coatings are derived from renewable resources like corn or potato starch. These coatings create a protective film over the paper bag, making it grease-resistant and moisture-tolerant—without using synthetic polymers.

They are biodegradable, compostable, and yes—Mother Nature gives them two thumbs up.

Pros:

- 100% biodegradable and compostable

- Derived from renewable materials

- Excellent for dry food packaging

Cons:

- Less durable in high-humidity environments

- Not always water-resistant enough for liquids or oily foods

Starch-based coatings are great for brands that want that “farm-to-table” vibe or serve mostly dry products like bread, snacks, or tea.

What Is PVOH (Polyvinyl Alcohol)?

Let’s get nerdy for a second—PVOH is a synthetic polymer that dissolves in water and is often used in laundry pods and food packaging. It’s not biodegradable in the traditional sense, but it is water-soluble and doesn’t leave harmful residues.

Pros:

- Water-soluble

- High barrier to oxygen and grease

- Can improve bag durability while keeping it eco-friendlier than PE

Cons:

- Requires specific waste management systems

- Higher cost than starch and water-based coatings

- Not always compatible with high-humidity supply chains

PVOH is ideal for businesses looking for stronger barrier properties, like packaging for oily or greasy foods. It’s also great for frozen food applications.

What About Water-Based Coatings?

Now we’re talking chemistry and innovation. Water-based coatings use aqueous dispersions of polymers, waxes, or bio-based materials to create moisture and grease resistance. These coatings are recyclable and, in some cases, compostable depending on the formulation.

At GreenWing, we’ve invested heavily in perfecting our water-based coating process because it hits that sweet spot: green, functional, and cost-efficient.

Pros:

- Recyclable and repulpable

- Excellent print compatibility

- No plastic film layer required

- Great for food service and takeaway bags

Cons:

- Barrier performance varies by formula

- Some options are not fully compostable

- May not perform well for high-oil content foods without extra layers

Water-based coatings are a crowd favorite right now—versatile, scalable, and fully aligned with the circular economy.

Which One Should You Choose?

Ah yes, the million-dollar question.

Here’s how I like to break it down for our clients:

| Coating Type | Best For | Eco Score 🌱 | Barrier Strength 💪 | Cost 💵 |

|---|---|---|---|---|

| Starch-Based | Dry food, compostable products | ⭐⭐⭐⭐⭐ | ⭐⭐ | $ |

| PVOH | Oily or high-barrier food items | ⭐⭐⭐ | ⭐⭐⭐⭐ | $$$ |

| Water-Based | General takeaway, food delivery | ⭐⭐⭐⭐ | ⭐⭐⭐ | $$ |

If your main goal is “get rid of PE but keep functionality,” I usually recommend water-based coatings. They’re the most balanced option for most food packaging applications.

What Are the Limitations of These Coatings?

No solution is perfect—yet.

- Starch-based coatings may struggle with high moisture environments.

- PVOH is eco-friendly under the right conditions but may confuse waste management systems.

- Water-based coatings need ongoing innovation to match PE-level barrier performance.

That’s why at GreenWing, we offer coating consultation and testing services. We help customers like Mike Baker (yes, looking at you, food brand buyers) figure out exactly what works for their SKUs, logistics chains, and customer values.

Are These Coatings Customizable?

Absolutely. One of our strengths at GreenWing is custom formulation. Want a starch base with a top coat of water-based wax? Done. Want PVOH that breaks down in marine environments? We’ve got contacts for that too.

Whether you need anti-grease, high-barrier, or heat-sealable features, we tailor our coatings to your product—without making your accountant cry.

More Related Questions

Can starch-based coatings be used for hot food packaging?

Only if there’s an added barrier layer. Alone, starch coatings may fail with heat and steam. We often blend it with other eco-barriers.

Are PVOH-coated bags recyclable?

Not in all systems. Some recycling centers can handle it, but many can’t. Always consult with your end-market recyclers.

What’s the most cost-effective coating?

Water-based coatings win here. They’re easy to scale, compatible with standard printing, and strike a good balance between function and price.

Are there certifications for these coatings?

Yes! Look for OK Compost, FDA Food Contact, and EU Regulation 1935/2004 depending on your market.

Conclusion

Choosing the right coating isn’t just a technical decision—it’s a brand move. Whether you’re into starch-based purity, PVOH power, or water-based flexibility, the key is aligning performance with your sustainability goals.

Want help deciding? That’s what we’re here for.