Moisture sneaks in.

Mold grows silently.

Brands get blamed loudly.

I’ve seen it happen too many times. A paper bag fails, not because of design, but because microbes got there first. The loss is real. The reputation damage is worse. That’s why anti-mold and antibacterial paper bags are no longer “nice to have”. They are survival tools.

So yes, anti-mold and antibacterial paper bags are real, effective, and increasingly necessary—but only when the right active agents, migration controls, and compliance strategies are used together. From my experience running a large-scale paper bag factory, success comes from understanding chemistry, process control, and regulations at the same time, not in isolation.

Stay with me.

This topic looks academic.

But it decides whether your packaging works in the real world.

Why Do Paper Bags Need Anti-Mold and Antibacterial Treatment?

Paper bags are everywhere now.

Food. Fashion. Pharma. Electronics.

They are sustainable.

They are printable.

They are also biological playgrounds.

Paper is hygroscopic.

It absorbs moisture fast.

High humidity equals microbial paradise.

In food packaging, mold means recalls.

In textiles, it means odor complaints.

In pharmaceuticals, it means compliance nightmares.

Long storage times make it worse.

Ocean shipping does not help.

From my side, treatment is not about over-engineering.

It’s about risk control.

Anti-mold and antibacterial solutions extend shelf life.

They reduce product loss.

They protect brand trust.

And yes, customers notice.

What Types of Active Agents Are Used in Antibacterial Paper Bags?

There is no single “best” agent.

Only trade-offs.

I always tell clients this:

If someone claims a perfect solution, run.

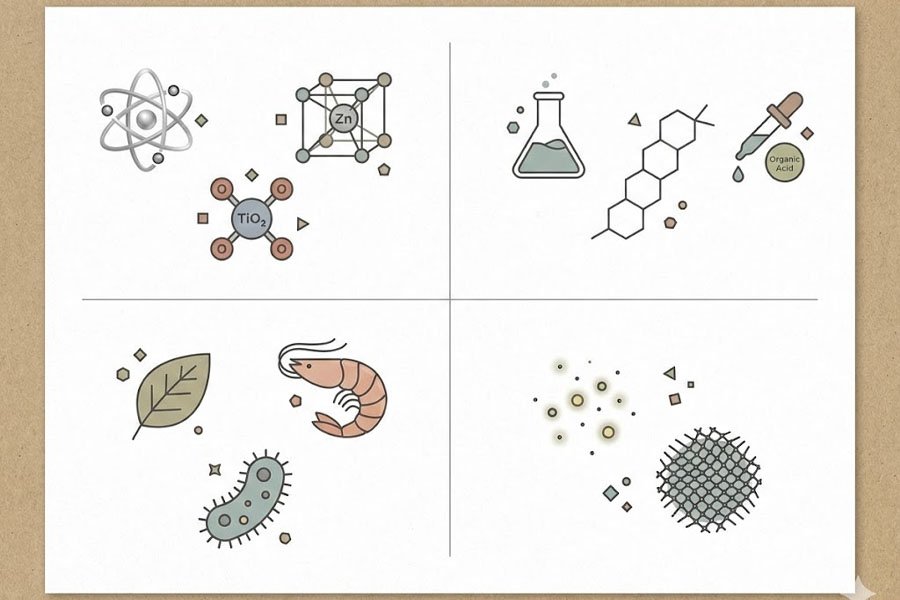

Inorganic Antibacterial Agents

Silver-based agents are famous.

They work by releasing Ag⁺ ions.

These ions disrupt microbial metabolism.

Broad-spectrum.

Heat resistant.

Long-lasting.

But silver is expensive.

Migration risk exists.

Discoloration can happen.

Copper-based agents work similarly.

Cheaper.

Stronger oxidation.

Also more risky.

Paper color changes easily.

Migration control becomes critical.

Zinc oxide is safer.

Lower toxicity.

UV resistant.

But particle size matters a lot.

Too big, weak effect.

Too small, dispersion issues.

Titanium dioxide relies on light.

Photocatalysis creates ROS.

Great in theory.

But darkness kills performance.

Most packages live in boxes.

What About Organic Antibacterial Agents?

Organic agents act fast.

They migrate easily.

That’s both power and danger.

Quaternary ammonium salts break cell membranes.

Strong.

Wide spectrum.

Also high migration risk.

Regulators watch them closely.

Isothiazolinones are efficient at low doses.

But they raise allergy concerns.

Use is restricted in many markets.

Organic acids feel familiar.

Sorbic. Benzoic. Propionic.

Food-safe reputation helps.

But they need high dosage.

pH dependence limits applications.

From my experience, organic agents demand strict testing.

Otherwise, they become compliance liabilities.

Can Natural Antibacterial Agents Really Work?

Yes.

But don’t romanticize them.

Essential oils sound attractive.

Tea tree. Thyme. Cinnamon.

They disrupt membranes naturally.

Consumers love the story.

But volatility is real.

Long-term effectiveness is weak.

Cost is high.

Chitosan is my favorite natural option.

Biodegradable.

Edible.

Positively charged.

But solubility limits process choices.

pH sensitivity matters.

Lysozyme and nisin are food legends.

Approved. Safe. Trusted.

Still, their antibacterial spectrum is narrow.

Cost adds pressure.

Natural agents work best when blended.

Never alone.

How Does Nanotechnology Change Antibacterial Paper Bags?

Nanomaterials amplify everything.

Including risks.

Nano-silver works efficiently.

Low dosage.

High surface area.

But regulators are cautious.

Environmental impact is debated.

Nano-ZnO offers better balance.

Safer profile.

Strong ROS generation.

Dispersion is key.

Aggregation ruins performance.

Nano-CuO is powerful.

Also controversial.

Compliance complexity rises fast.

My rule:

Nanotech without migration control is reckless.

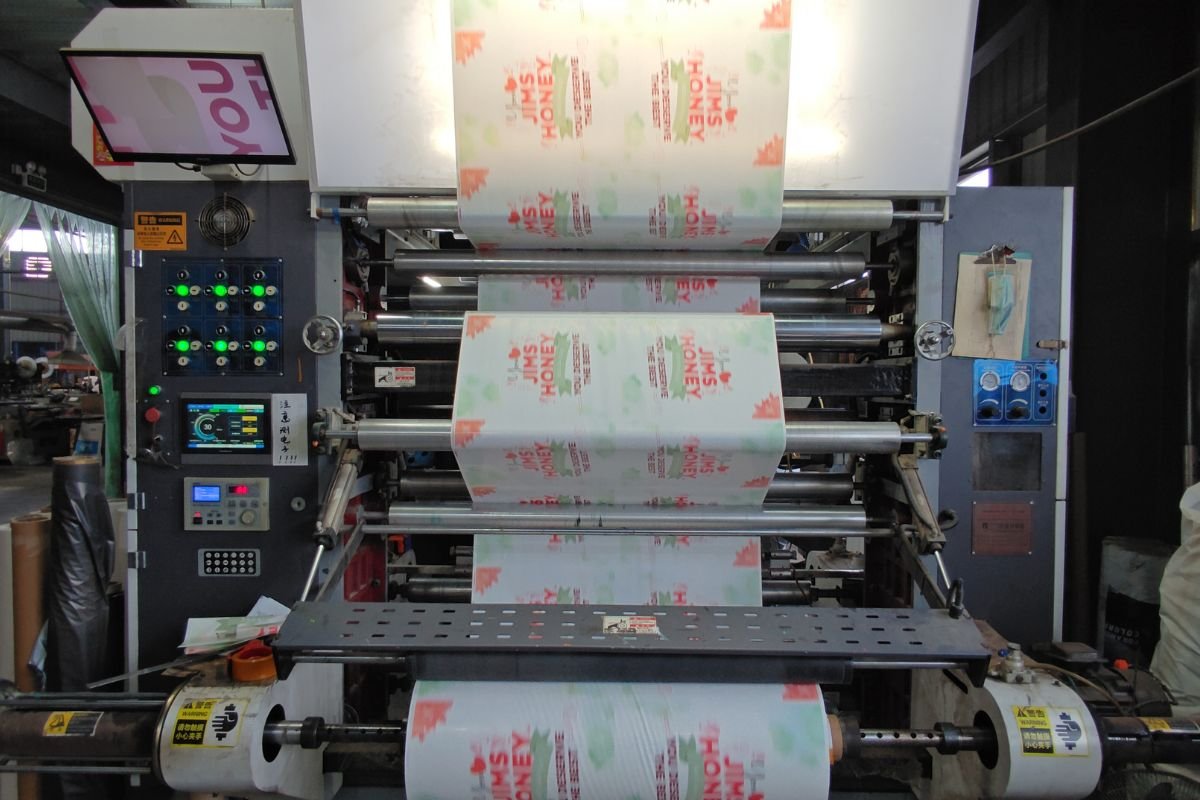

How Are Antibacterial Agents Applied to Paper Bags?

Chemistry is only half the story.

Process decides success.

Coating is common.

Simple. Scalable.

But surface migration risk is high.

Texture changes happen.

Impregnation goes deeper.

Uniform distribution.

Longer effect.

But paper strength may drop.

Chemical consumption increases.

In-situ synthesis bonds agents to fibers.

Migration reduces dramatically.

Also complexity rises.

Costs follow.

Spraying allows precision.

Local treatment is possible.

Composite coatings mix polymers like PLA or PE.

Barrier improves.

Migration drops.

But recyclability suffers.

Trade-offs again.

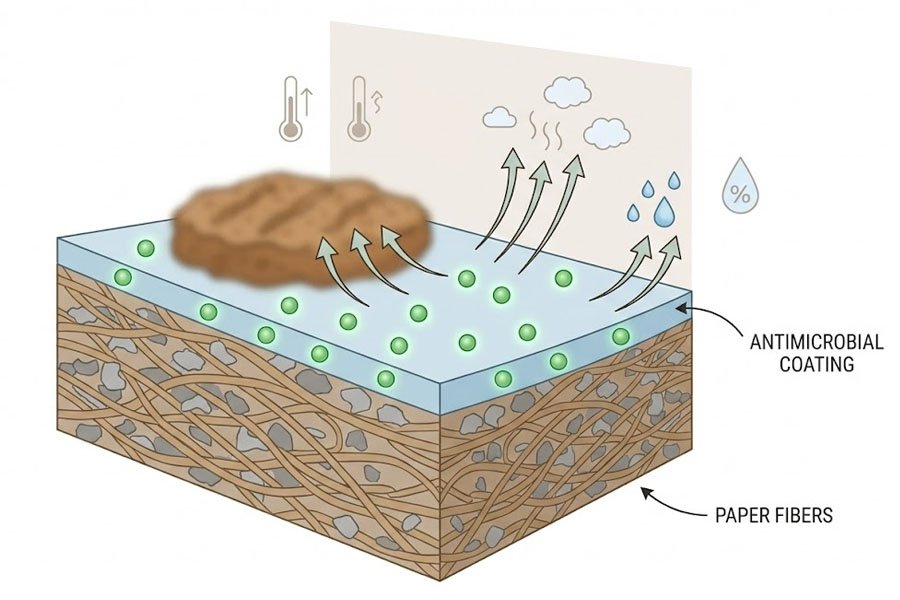

What Causes Migration Risks in Antibacterial Paper Bags?

Migration is physics, not opinion.

Diffusion never sleeps.

Concentration always equalizes.

Moisture dissolves agents.

Grease accelerates movement.

Small molecules migrate faster.

Porous paper invites travel.

Temperature speeds everything up.

Time is the silent killer.

That’s why testing matters.

Overall migration tests show total transfer.

Specific migration tests track substances like silver ions.

Toxicology defines acceptable limits.

ADI values are non-negotiable.

Skipping this step is gambling.

What Compliance Rules Must Antibacterial Paper Bags Meet?

This is where many suppliers fail.

In the EU, EC No 1935/2004 rules all food contact materials.

Active substances trigger BPR scrutiny.

Silver limits exist.

Overall migration caps apply.

In the US, FDA 21 CFR Part 176 governs paper.

Only approved FCS or GRAS substances are allowed.

China follows GB 4806 and GB 9685.

Additives must be listed.

Limits are strict.

Biocidal classification complicates things further.

EPA. EU BPR. Registration matters.

Environmental rules add another layer.

RoHS. REACH. Heavy metals.

Compliance is not paperwork.

It’s strategy.

How Do We Reduce Migration Risks in Practice?

This is where engineering shines.

Chemical immobilization binds agents to fibers.

Migration drops sharply.

Microencapsulation controls release rates.

Performance stabilizes.

Barrier coatings block movement physically.

Nanoclay and nanocellulose help.

Choosing high molecular weight agents reduces mobility.

Blending lowers dosage.

Testing under real conditions matters.

Humidity. Heat. Time.

Third-party certification builds trust.

Not slides. Not promises.

What Are the Industry Challenges and Future Trends?

The road ahead is not simple.

Regulations differ globally.

Costs rise.

Performance expectations increase.

Consumers want “natural”.

But demand performance too.

The future is greener agents.

Smarter packaging.

Better nanocontrol.

Sensors may join packaging soon.

Circular economy designs will dominate.

From where I stand, the winners will be those who balance science, compliance, and honesty.

Conclusion

Anti-mold and antibacterial paper bags are not just chemical products. They are systems. Active agents, migration control, and compliance must work together. The future belongs to safer, smarter, and more sustainable solutions—and to companies that respect both science and regulation.