Every packaging buyer I talk to these days faces the same problem: how to keep their food products dry, aromatic, and fresh—without using plastic. Customers demand sustainability, but brands can’t risk soggy cookies or coffee that’s lost its aroma. I’ve been there myself when we tested our first eco-friendly paper bag line. It was… let’s say, a learning curve.

The good news? Paper bags can achieve moisture and aroma barrier performance without plastic lamination. Through advanced coatings, natural materials, and clever engineering, we can create functional barriers while keeping the entire package recyclable and compostable. It’s no longer a dream—it’s here, and it’s commercially viable.

Let’s dig in.

Why Is This Challenge So Important?

With global plastic restriction policies tightening every year, food and beverage brands are racing to reduce their environmental footprint. Coffee, tea, and bakery industries in particular face a double challenge: they need to preserve freshness and meet eco-compliance standards.

Consumers may not think about it, but moisture and aroma protection define product quality. Once your coffee loses aroma, it’s not “specialty” anymore—it’s just bitter powder. And that’s a disaster for brand perception.

The Core Problem: Paper Alone Can’t Block Moisture or Aroma

Here’s the technical truth: pure paper, no matter how thick, has a high Water Vapor Transmission Rate (WVTR) and poor oxygen barrier. Moisture sneaks in, aroma sneaks out. Traditional paper packaging used plastic lamination—usually polyethylene (PE)—to solve this.

But PE-laminated paper can’t be recycled in paper streams. That’s a big no-no in the post-2020 market. So, how do we replace plastic without losing performance?

Solution 1: Water-Based Coatings—The Green Chemistry Revolution

This is where things get exciting.

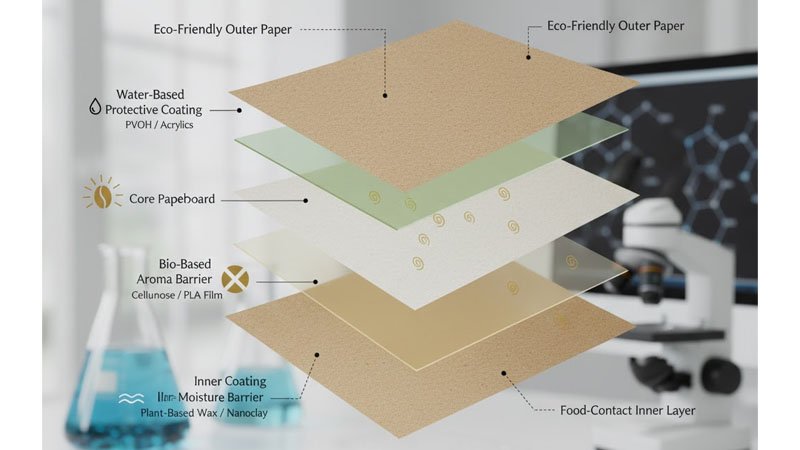

At GreenWing, we’ve been exploring PVOH (polyvinyl alcohol), acrylic, protein-based, and nanocellulose coatings. Each has unique strengths:

- PVOH coatings deliver excellent moisture barrier and are water-soluble and biodegradable

- Acrylic coatings resist both water and grease—perfect for snacks or bakery items.

- Protein coatings from whey or soy offer natural film formation, improving aroma retention.

- Nanocellulose coatings use ultra-fine plant fibers to create dense barriers, though cost and scalability are still challenges.

When applied correctly, these coatings form an invisible armor—thin, light, yet powerful.

Solution 2: Bio-Based Films—The Next Generation of Barriers

Plastic-free doesn’t mean film-free. We now have PLA, PBAT, and cellulose-based films like NatureFlex.

- PLA (polylactic acid) is compostable and offers decent moisture resistance.

- PBAT adds flexibility, making packaging less brittle.

- Cellulose films are outstanding in oxygen barrier performance, great for preserving aroma in coffee or tea bags.

By combining these films with kraft paper, we can produce lamination-free barrier paper bags that remain 100% recyclable or compostable.

Solution 3: Wax Coatings—Old School, New Tricks

Remember when everything from chocolate to cheese was wrapped in wax paper? Turns out, that idea is back.

Plant-based waxes like soybean, carnauba, or beeswax form natural hydrophobic layers. They repel moisture, improve stiffness, and even add a gentle sheen.

We’ve been experimenting with hot-melt coating and dipping processes—no solvents, no plastic, just natural protection. And the aroma barrier performance? Surprisingly impressive.

Solution 4: Mineral and Nanoclay Coatings—Earth’s Own Barrier Layer

Here’s a fascinating frontier: kaolin, talc, and montmorillonite coatings.

These minerals create a tortuous path for water molecules—think of it as a microscopic maze. Moisture can’t easily pass through, improving WVTR significantly.

The best part? Minerals are abundant, safe, and compatible with standard paper coating lines. We’re currently testing hybrid formulations combining clay with bio-binders to boost performance and recyclability.

How Do We Measure Performance?

We don’t just guess. Every GreenWing test line follows global standards:

- Water Vapor Transmission Rate (WVTR) under ASTM E96

- Cobb test for water absorption

- Oxygen Transmission Rate (OTR) for aroma retention

- Food safety certifications under FDA 21 CFR and EU 10/2011

For context, a good barrier paper should target WVTR < 20 g/m²·24h and Cobb60 < 30 g/m². Achieving this without plastic means we’re hitting high performance on eco terms.

Who Needs These Solutions Most?

Our main customers—coffee brands, bakery chains, pet food manufacturers, and tea companies—all face similar pain points:

- Keeping product freshness during overseas shipping

- Meeting certification standards like EN 13432 and BPI Compostable

- Avoiding delays from complex material approvals

- Balancing cost vs performance

We’ve helped several U.S. clients upgrade to PVOH-coated paper bags that reduced moisture ingress by 70% while remaining recyclable. That’s what sustainable innovation should look like—no compromise between eco and efficiency.

The Cost Factor—Is It Worth It?

This is where your procurement brain kicks in. Water-based coatings are 10–25% more expensive per m² compared to standard PE lamination.

But—and it’s a big but—when you factor in savings on recycling costs, waste management, and green branding ROI, the long-term economics are surprisingly favorable.

In other words, going plastic-free is not just ethical, it’s smart business.

The Future of Barrier Paper: Multi-Layer and Smart Solutions

We’re already experimenting with multi-coating systems—a thin layer of nanocellulose plus a plant wax topcoat, for example. Early results show double-digit improvements in moisture protection.

The next wave? Smart coatings with active ingredients that absorb oxygen or neutralize odor. Imagine packaging that helps preserve freshness by design.

Research institutions and packaging innovators are collaborating intensively. It’s an exciting time to be in this industry.

More Related Questions

Can these coatings be composted industrially?

Yes. PVOH, PLA, and cellulose-based coatings are all EN 13432-certified compostable. Just avoid mixing with synthetic binders.

Are the bags still printable?

Absolutely. Water-based and protein coatings work beautifully with flexo and gravure printing, maintaining vivid colors and no ink bleeding.

How scalable are these solutions?

High. GreenWing already operates automatic coating and bag-making lines capable of 5 million bags per day—proving these technologies are beyond lab-scale.

Do they pass food-contact safety tests?

Yes. All materials used comply with FDA 21 CFR 176.170 and EU 10/2011 standards.

Conclusion

We’ve reached a point where paper bags can stand toe-to-toe with plastic laminates—on performance, protection, and sustainability.

At GreenWing, we don’t see it as just a packaging upgrade. We see it as a promise—to our planet, to our partners, and to every roasted coffee bean that deserves to arrive aromatic and fresh.

Because, in the end, the best barrier isn’t plastic—it’s innovation.