Paper packaging is hot. Everybody wants eco-friendly, sustainable, customizable. Sounds like a win, right? But beneath the smooth kraft surface, our industry is weathering storms—raw material spikes, greenwashing, and supply chain chaos. It’s not all paper roses.

The paper packaging industry is facing significant challenges including raw material shortages, rising costs, recycling limitations, and tightening regulations. But with innovation, automation, and strategic partnerships, companies like GreenWing are not just surviving—we’re scaling.

Curious what’s really happening behind the curtain? Let me unpack it for you.

Are Raw Material Shortages Choking the Industry?

Let’s start with the most obvious: paper pulp supply.

Over the last few years, we’ve seen:

- Pulp prices spike by over 30%

- Import restrictions from major suppliers like Canada and Indonesia

- Domestic overconsumption from the e-commerce boom

As a manufacturer, I can tell you—we feel it daily. At GreenWing, we mitigate this by pre-purchasing in bulk and having diversified supplier networks. But for smaller players? It’s tough.

And let’s not forget the pandemic aftershocks. Supply chains are still finding their rhythm.

Can We Afford These Rising Costs?

If you’ve checked pricing lately, you’ve probably said a few things we can’t print here.

Between:

- Fuel surcharges

- Labor wage increases

- Machinery maintenance

- Certifications and audits

…our cost of production has ballooned.

And no—paper bags aren’t “cheap” just because they’re paper. When customers ask why prices have increased, I tell them the truth: we’re absorbing as much as we can, but we’re not magicians.

We try to ease the burden with bulk discounts, optimized bag designs, and lean production. But the cost pressure? It’s real.

For paper packaging cost analysis: Check updated market pricing here

Is Recycling Paper Really as Easy as It Sounds?

Ah yes—sustainability. Everyone loves the word.

But let’s get real.

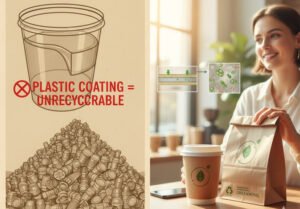

Most people think paper = recyclable = guilt-free. But coated paper, laminated bags, bags with food grease? Not so simple.

In fact, many curbside recycling programs reject food-stained paper. Even uncoated kraft becomes problematic when wet or contaminated.

At GreenWing, we design bags with recyclability in mind—mono-materials, water-based inks, easy-tear features. But the system? It’s not perfect.

Until municipalities improve infrastructure and educate consumers, recyclability remains a partial promise.

Are Regulations Helping or Hurting?

Don’t get me wrong—I support environmental policy.

But lately, the rules are a moving target.

We’ve seen:

- Europe tighten compostable labeling laws

- California mandate PFAS-free packaging

- Canada restrict single-use bag thicknesses

All of this means constant re-certification, product redesigns, and educating customers. It slows innovation.

Plus, for global exporters like us, different rules in different regions = nightmare. One spec works in Germany, but not in Ontario. So we build flexibility into our production lines. It’s a dance.

Greenwashing: Who’s Telling the Truth?

Now, here’s the elephant in the kraft-paper room.

Not every “eco-friendly” label is legit.

Some brands slap on a leaf logo, call it “green,” and walk away. No testing. No certification. No accountability.

This not only misleads customers, but undermines companies like us who spend thousands on real compliance—FSC®, ISO 22000, SGS audits, and more.

The solution? Transparency.

At GreenWing, we offer documentation with every order. You want to know the source of your pulp? I’ll give you the GPS coordinates.

Labor & Automation: Who’s Making the Bags?

Labor is a double-edged sword.

- In countries with rising wages (like China), labor costs are increasing fast.

- In low-wage regions, quality and training become huge concerns.

That’s why GreenWing invested in 100+ automatic bag-making machines. Machines don’t strike. Machines don’t call in sick. And machines—when tuned right—deliver consistent quality 24/7.

Still, we don’t fully replace people. Our engineers, QC staff, and packers are the backbone of our operations. But we supplement them with tech. It’s the only way to scale without sacrificing quality.

Customer Expectations: Are We Chasing Moving Targets?

Let’s talk about you, our customers.

You want:

- 3-day samples

- 2-week turnaround

- Eco-certification

- Custom printing

- And oh yes, rock-bottom pricing

All at once.

I get it—you’re under pressure too. Retail deadlines, logistics, margins, reviews. But here’s the truth:

The Amazon-ification of packaging is unsustainable. Not every product can be made custom, fast, and cheap. Something has to give.

At GreenWing, we bridge the gap with:

- 24/7 customer support (yes, real humans)

- Fast-tracked sample kits

- Modular design templates to cut time

- Realistic, honest timelines

Because if we all chase speed and price, we’ll kill the very quality that built our industry.

What Keeps Me Up at Night?

I’ll tell you what it’s not: competition.

There’s plenty of space in this market for good players. What keeps me up is the disconnect between expectations and reality.

- The myth that paper is always cheaper

- The idea that sustainability is effortless

- The assumption that Chinese suppliers can scale overnight

My job—as your supplier—is not just to make bags. It’s to help you win in a brutally competitive market with packaging that’s functional, ethical, and beautiful.

More Questions You Might Be Asking

Why is there still plastic inside some paper bags?

Some paper bags (especially for greasy food) use inner PE liners to prevent leakage. But don’t worry—we also offer compostable and bio-coating options.

Are paper bags better than plastic?

For branding and biodegradability—yes. For moisture resistance and price? Not always. It’s about application.

How do I ensure my supplier isn’t greenwashing?

Ask for certifications—FSC®, BRC, ISO, compostability reports. If they can’t provide documentation, run.

Can I customize bags with short lead times?

Yes—if you work with a partner who has digital printing capabilities and pre-stocked paper grades. (Hint: that’s us.)

Conclusion

The paper packaging industry isn’t falling apart—it’s transforming.

Yes, we face challenges. But with the right partners, the right machines, and the right mindset, we’re not just surviving—we’re evolving.

So whether you’re sourcing your first bag or scaling into seven figures, choose a supplier who’s honest about the hurdles and knows how to leap over them.